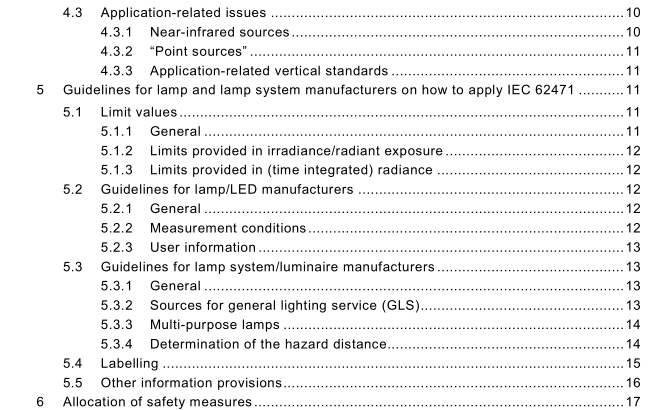

IEC TR 62471-2:2009 pdf download – Photobiological safety of lamps and lamp systems – Part 2: Guidance on manufacturing requirements relating to non-laser optical radiation safety

5.1.2 Limits provided in irradiance/radiant exposure In the spectral ranges 200 nm to 400 nm and 1 400 nm to 3 000 nm where the emission limits in IEC 62471 are provided in irradiance or radiant exposure, the measurements of a single lamp can not simply be transferred directly to a lamp system but require an analysis of the optical additivity to determine the system risk group. When a lamp is employed with additional integrated or attached modifying or projection optics, this lamp system should be considered as a different product and the lamp system manufacturer should provide the new risk group safety classification. NOTE Additional optics primarily modify the irradiance of a source (i.e. may have a significant impact where the classification is based on irradiance or radiant exposure-criteria), whereas the radiance may remain unchanged (i.e. less impact where the classification is based on radiance-criteria).

5.1.3 Limits provided in (time integrated) radiance In cases where the emission limits in IEC 62471 are provided in terms of spatially averaged radiance or time-integrated spatially averaged radiance, the principle of conservation of radiance may be used with caution. That is, if a lamp or single LED emits below the radiance level specified (per risk group), the final lamp system or LED-array also can not exceed the accessible emission limits. IEC 62471 requires measurements of spatially averaged radiance (3.1 5) values with the consequence that the relationship between the field of view and the source area, as it was used for the characterisation of a single component, may be changed by the integration of the single lamp or LED into luminaries (arrays) or with the attachment of beam-shaping optics.

Under specific conditions (see 5.2.2), the assessment of a single lamp/LED is directly transferable to the lamp system or luminaire. The risk group will remain the same, or may be reduced (e.g., by filters, etc.). NOTE Since additional optics primarily modify (increase) the irradiance of a source rather than the radiance, an evaluation should verify that the most restrictive classification criterion of the lamp system has not been changed (from radiance to irradiance criterion).

5.2 Guidelines for lamp/LED manufacturers

5.2.1 General The primary purpose of lamp risk-group classification by the lamp or LED manufacturer is to inform the user or final-product manufacturer of potential hazards that may need to be addressed in the safety design of the final product. Therefore, when a lamp is placed in Risk Groups 1 , 2 or 3, it is important for the user to be informed of which potential hazards may require controls. If the manufacturer provides the EHV or HD for the lamp (see 5.3.4), the determination of appropriate controls can be simplified.

5.2.2 Measurement conditions In the range 200 nm to 400 nm or 1 400 nm to 3 000 nm where the limits in IEC 62471 are provided in irradiance or radiant exposure, the measurements should be performed according to IEC 62471 . In cases where the limits in IEC 62471 are provided in spatially averaged radiance or time- integrated radiance, the source radiance (according to 3.1 4) data should be determined (LEDs: operating under maximum operating conditions, such as maximum current) according to IEC 62471 . The angle of acceptance should be 1 ,7 mrad in any case. NOTE These values should be compared with the risk group-specific limit values (rather than apply different angles of acceptance). Under these conditions it can be assured that the risk group allocation of the component in any case is directly transferable and useful to the characterisation of the final lamp system.

If the use of the product is known and unambiguous, the application-specific requirements (i.e. vertical standards) should be applied, where these exist, or subclauses 4.2 and 4.3 should be applied.IEC TR 62471-2 pdf download.