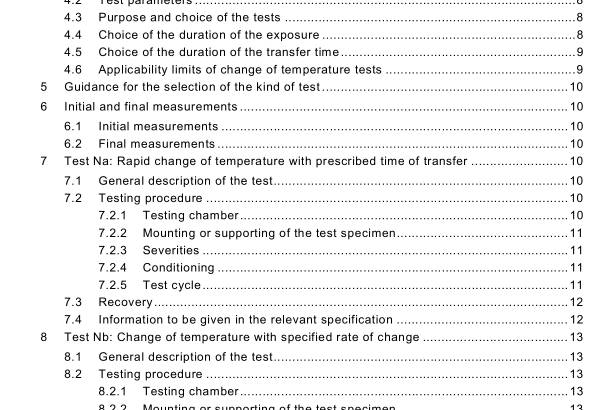

IEC 60068-2-14:2009 pdf download – Environmental testing Part 2-14: Tests Test N: Change of temperature

In particular cases, such as with specimens sensitive to water, a test with liquid other than water may need to be specified. When designing such a test, the characteristics of heat transfer of the liquid, which may differ from those of water, shall be taken into account. NOTE To assess the applicability of the two-bath method, evaluations from Test Q: Sealing (IEC 60068-2-1 7) may be helpful. 5 Guidance for the selection of the kind of test The severity of the test will increase with the increase in the temperature difference, the increase in rate of temperature change, and the heat transfer to the specimen. The application of Tests N is preferred as part of a sequence of tests. Some types of damage may not become apparent by the final measurements of a Test N, but may appear only during subsequent tests (e.g. Test Q: Sealing, Test F: Vibration or Test D: Accelerated damp heat). The change of temperature Test Nc (Two-bath method) should not be used as an alternative to Test Q (Sealing). When specifying a change of temperature test, the properties of the objects under test which are affected by conditions of changing temperature, and their possible failure mechanisms, should be kept in mind. The initial and the final measurements should be specified accordingly. 6 Initial and final measurements Tests Na, Nb and Nc all use the same initial and final measurements.

6.1 Initial measurements The specimen shall be visually examined and electrically and mechanically checked as required by the relevant specification.

6.2 Final measurements The specimen shall be visually examined and electrically and mechanically checked, as required by the relevant specification.

7 Test Na: Rapid change of temperature with prescribed time of transfer

7.1 General description of the test This test determines the ability of components, equipment or other articles to withstand rapid changes of ambient temperature. The exposure times adequate to accomplish this will depend upon the nature of the specimen. The specimen shall be either in the unpacked, switched-off, ready for use state, or as otherwise specified in the relevant specification. The specimen is exposed to rapid changes of temperature in air, or in a suitable inert gas, by alternate exposure to low temperature and to high temperature.

7.2 Testing procedure

7.2.1 Testing chamber Two separate chambers or one rapid temperature change rate chamber may be used. If two chambers are used, one for the low temperature and one for the high temperature, the location shall be such as to allow transfer of the specimen from one chamber to the other within the prescribed time. Either manual or automatic transfer methods may be used.

The chambers shall be capable of maintaining the atmosphere at the appropriate temperature for the test in any region where the specimen is placed. After insertion of the test specimens, the air temperature shall be within the specified tolerance after a time of not more than 1 0 % of the exposure time.

7.2.2 Mounting or supporting of the test specimen Unless otherwise specified in the relevant specification, the thermal conduction of the mounting or supports shall be low, such that for practical purposes the specimen is thermally isolated. When testing several specimens simultaneously they shall be so placed that free circulation shall be provided between specimens, and between specimens and chamber surfaces.

7.2.3 Severities The severity of the test is defined by the combination of the two temperatures, the transfer time, the exposure time of the specimen and the number of cycles. The lower temperature, T A , shall be specified in the relevant specification and should be chosen from the test temperatures of IEC 60068-2-1 and IEC 60068-2-2. The higher temperature, T B , shall be specified in the relevant specification and should be chosen from the test temperatures of IEC 60068-2-1 and IEC 60068-2-2. The exposure time, t 1 , of each of the two temperatures depends upon the heat capacity of the specimen. It may be 3 h, 2 h, 1 h, 30 min or 1 0 min, or as specified in the relevant specification. Where no exposure period is specified in the relevant specification, it is understood to be 3 h. The preferred number of test cycles is five, unless otherwise specified in the relevant specification.