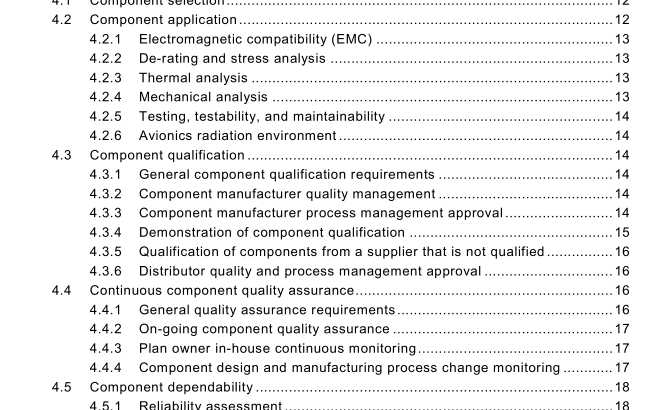

IEC TS 62239:2008 pdf download – Process management for avionics – Preparation of an electronic components management plan

4.2.5 Testing, testability, and maintainability

The documented processes shall assure testability and maintainability of the equipment by the plan owner.

NOTE 1 The focus here is on testing and testability with regard to component verification, not on software or system verification. Examples include board level or sub-assembly level testing, provision for test pins, and that other equipment level tests will be available to verify component function at the appropriate level. Exhaustive testing of complex components is not always realistic, but documented processes should assure some level of evaluation of all components at appropriate points in the production flow.

NOTE 2 This requirement also includes design for maintainability, for example, placement for ease of component replacement, mounting that minimises the risk of damage during maintenance and assures equipment quality following maintenance or repair by equipment manufacturer.

4.2.6 Avionics radiation environment The documented processes shall verify that the components will operate successfully in the application with regard to the effects of atmospheric radiation on them. These include various types of single event effects (SEE), such as single event upset (SEU), single event latch-up (SEL), and single event burnout (SEB). If radiation effects are accommodated by the equipment design, than the method of accommodation shall be documented in the equipment design records. Guidance on the effects of atmospheric radiation may be found in the IEC/TS 62396 series. The effects of atmospheric radiation and their accommodation shall be assessed and documented in accordance with the SEE compliance considerations of the IEC/TS 62396 series.

4.3 Component qualification

4.3.1 General component qualification requirements It is desired and expected that the majority of components be obtained from qualified component manufacturers; in which case the requirements of 4.3.2, 4.3.3, and 4.3.4 shall apply. In cases where the component manufacturer is not qualified, the requirements of 4.3.5 shall apply.

4.3.2 Component manufacturer quality management The plan owner shall verify that the component manufacturer has a documented quality management system.

4.3.2.1 The component manufacturer shall have a quality system assessed to the relevant parts of the ISO 9000 series or equivalent.

4.3.2.2 Where the component manufacturer is not assessed in accordance with 4.3.2.1 above or an approved existing scheme, then the plan owner shall demonstrate how the quality management system of the component manufacturer shall be maintained. Where the plan owner conducts or enables an audit on the component manufacturing facility, then the audit shall be conducted in accordance with the relevant standards of the ISO 9000 series or equivalent system. Suitably trained auditors shall conduct that audit.

4.3.3 Component manufacturer process management approval The plan owner shall verify that the component manufacturer has a manufacturing process capability utilising manufacturing technologies with demonstrable repeatability. This may be satisfied by one of the following:

4.3.3.1 Manufacturing approval of the component technologies by a third party (for example DSCC, IECQ, STACK S/0001 ) or within an international second party system.

4.3.3.2 Where the component manufacturer is not assessed as in 4.3.3.1 above, then the plan owner shall demonstrate how the process management capability of the component manufacturer is ensured. Where the plan owner conducts or enables an audit on the component manufacturing facility, then the audit shall be conducted in accordance with one of the above systems (as in 4.3.3.1 above) by suitably accredited auditors.

4.3.3.3 Manufacturers who do not have an appropriate internal quality management system may be used when their products are fully qualified by the plan owner in accordance with 4.3.4.2.

4.3.4 Demonstration of component qualification The plan owner shall document the component qualification process for each component. The qualification plan and test procedures, sampling and criteria of acceptance (with the de- fined margins) shall be described. The approach to quality and reliability required in the application shall be outlined.