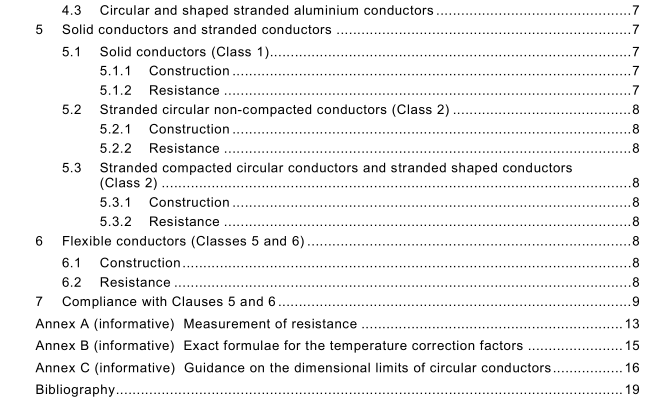

IEC TR 62602:2009 pdf download – Conductors of insulated cables – Data for AWG and KCMIL sizes

1 Scope

IEC/TR 62602, which is a technical report, specifies the nominal cross-sectional areas, in the range 20 AWG to 2 000 kcmil (0,52 mm 2 to 1 01 0 mm 2 ), for conductors in electric power cables and cords for a wide range of types. Requirements for numbers and sizes of wires and resistance values are also included. These conductors include solid and stranded copper, aluminium and aluminium alloy conductors in cables for fixed installations and flexible copper conductors. This technical report is not intended to apply to conductors designed for use in cables intended for telecommunication or data transmission, winding wires or similar products.

Unless indicated to the contrary in a particular clause, this technical report relates to conductors in finished cables and not to conductors made or supplied for inclusion into a cable. The annexes give supplementary information covering measurement of resistance (Annex A), temperature correction factors for resistance measurement (Annex B) and dimensional limits of circular conductors (Annex C).

2 Terms and definitions

For the purposes of this document, the following definitions apply.

2.1

metal-coated

coated with a thin layer of suitable metal, such as tin or tin alloy

2.2

nominal cross-sectional area

value that identifies a particular size of conductor but is not subject to direct measurement

NOTE Each particular size of conductor in this technical report is required to meet a maximum resistance value.

3 Classification

The conductors have been divided into four classes, 1 , 2, 5 and 6. Those in Classes 1 and 2 are intended for use in cables for fixed installations. Classes 5 and 6 are intended for use in flexible cables and cords but may also be used for fixed installations:

– Class 1 : solid conductors;

– Class 2: stranded conductors;

– Class 5: flexible conductors;

– Class 6: flexible conductors which are more flexible than Class 5.

4 Materials

4.1 General

The conductors consist of one of the following:

• plain or metal-coated annealed copper;

• aluminium or aluminium alloy.

4.2 Solid aluminium conductors

Circular and shaped solid aluminium conductors are made from aluminium such that the tensile strength of the completed conductor is within the following limits:

NOTE The values given above are not applicable to aluminium alloy conductors.

4.3 Circular and shaped stranded aluminium conductors

Stranded aluminium conductors are made from aluminium such that the tensile strength of the individual wires is within the following limits:

NOTE 1 The values given above are not applicable to aluminium alloy conductors.

NOTE 2 This data can only be checked on wires taken before stranding and not on wires taken from a stranded conductor.

5 Solid conductors and stranded conductors

5.1 Solid conductors (Class 1)

5.1.1 Construction

a) Solid conductors (Class 1 ) consist of one of the materials specified in Clause 4.

b) Solid copper conductors are of circular cross-section.

NOTE Solid copper conductors having nominal cross-sectional areas of 21 mm 2 and above are for particular types of cable, e.g. mineral insulated, and not for general purposes.

c) Solid aluminium and solid aluminium alloy conductors of sizes 3,3 mm 2 to 34 mm 2 are of circular cross-section. Larger sizes are of circular cross-section for single-core cables and may be of either circular or shaped cross-section for multi-core cables.

5.1.2 Resistance

The resistance of each conductor at 20 °C, when determined in accordance with Clause 7,

does not exceed the appropriate maximum value given in Table 1 .

5.2 Stranded circular non-compacted conductors (Class 2)

5.2.1 Construction

a) Stranded circular non-compacted conductors (Class 2) consist of one of the materials specified in Clause 4.

b) The wires in each conductor all have the same nominal diameter.

c) The number of wires in each conductor is not less than the appropriate minimum number given in Table 2.

5.2.2 Resistance

The resistance of each conductor at 20 °C, when determined in accordance with Clause 7,does not exceed the appropriate maximum value given in Table 2.