IEC 62561-4:2010 pdf download – Lightning protection system components (LPSC) – Part 4: Requirements for conductor fasteners

5.3.2lmpact tests

Conductor fasteners shall be so designed and constructed to withstand impact stressescaused accidentally.

Compliance is checked by test specified in 6.4.3.

5.4lnstallation instructions

The manufacturer or supplier of the conductor fastener shall provide adequate information inhis literature to ensure that the installer can select and install the component in a suitable andsafe manner, in accordance with lEC62305-3.

Compliance is checked by inspection in accordance with 6.5.

5.5Marking

Each conductor fastener shall be marked with

– the manufacturer’s or responsible vendor’s name or logo or trademark,- product identification or type.

Where it is not possible to make these marks directly onto the product, they shall be made onthe smallest supplied packaging.

NOTE Marking may be applied for example by moulding,pressing, engraving,printing adhesive labels or waterslide transfers.

Compliance is checked in accordance with 6.6.

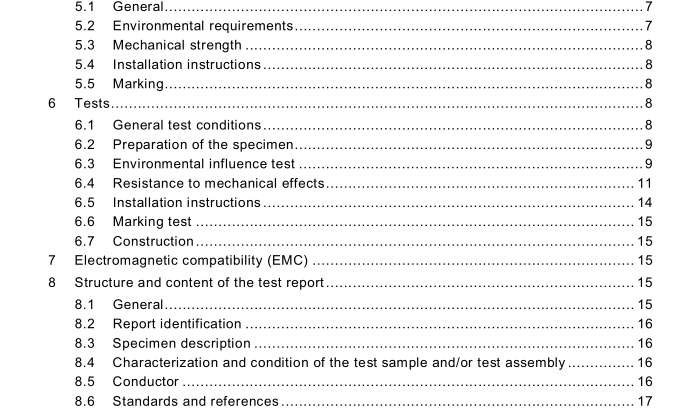

6 Tests

6.1General test conditions

Tests specified in this standard are type tests.These tests are of such a nature that,afterthey have been performed,they need not be repeated unless changes are made to thematerials,design’ or type of manufacturing process,which might change the performancecharacteristics.

The standard cannot cover all possible types of conductor fasteners and the way of fixingthem on various surfaces of different materials. When required,for these applications,agreement should be obtained between the test engineer and manufacturer on the specifictesting regime.

Unless otherwise specified, tests are carried out with the specimens assembled and installedas in normal use specified in the manufacturer’s or supplier’s instructions,with therecommended conductor materials,sizes and the tightening torques.

The tests shall be carried out in the sequence given after environmental tests of the specimenin accordance with 6.3.

Unless otherwise specified,12 metallic or 18 composite/non metallic specimens are subjectedto the tests and the requirements are satisfied if ail the tests are met.

lf only one of the specimens fails to satisfy a test due to a manufacturing fault, that test andany preceding one which may have influenced the results of the test shall be repeated andalso the tests which follow shall be made in the same required sequence on another full set ofsamples, all of which shall comply with the requirements.

Tests for non-metallic conductor fasteners shall not commence earlier than 168 h from thetime of their manufacturing.

A torque meter shall be used for all tightening operations. lt shall have a resolution of at least0,5 Nm and an accuracy of土 4 % or less.

The applicable tolerance for any applied mechanical load shall be within ±5 %.

NOTE The applicant, when submitting the first set of samples, may also submit an additional set of samples thatmay be necessary should one sample fail. The testing laboratory shall then,without further request,test theadditional set of samples,and shall only reject if a further failure occurs. If the additional set of samples is notsubmitted at the same time, a failure of one sample shall entail rejection.

6.2Preparation of the specimen

lf not otherwise specified by the manufacturer,the conductors and specimens shall becleaned by using a suitable degreasing agent followed by cleaning in demineralized water anddrying. They shall then be assembled in accordance with the manufacturer’s installationinstructions, e.g. with the recommended conductors and the tightening torques.

The tightening torque should be applied in a steady and uniform manner.

Any conductor fastener accommodating conductors with differences in size (diameter,thickness and width) equal to or less than 2 mm shall be tested using the minimum conductorsize recommended. lf the range is greater than 2 mm, the conductor fastener shall be testedusing the minimum and maximum of conductor sizes.

6.3 Environmental influence test

6.3.1 General

In order that a conductor fastener meets the requirements of this standard,environmentaltests shall be carried out according to Annex A and/or Annex B.

The selection of the tests to be performed depends upon the conductor fastener material.Annex C provides a flow chart relating the tests identified in 6.3.2,6.3.3 and 6.3.4 to theconductor fastener material.

NOTE The sequence of performing the UV test prior to the salt mist test for composite fasteners is becauseduring the salt mist test the specimen is covered by a salt layer. This would inhibit the Uv exposure test.IEC 62561-4 pdf download.