IEC 62467-1:2009 pdf download – Medical electrical equipment – Dosimetric instruments as used in brachytherapy – Part 1: Instruments based on well-type ionization chambers

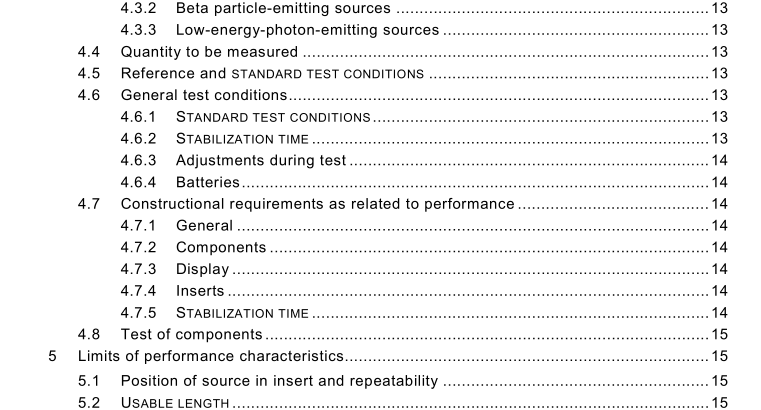

4.6.3 Adjustments during test Compliance tests shall be performed with the instrument under test ready for use, after the STABILIZATION TIME and after making any necessary preliminary adjustments. During the tests, adjustments may be repeated at intervals as long as they do not interfere with the effect to be verified. For example, zero setting is not permitted during tests for measuring the LEAKAGE CURRENT .

4.6.4 Batteries Battery-operated instruments under test shall be equipped with fully charged batteries, of the type specified by the MANUFACTURER , unless operating on an external power source.

4.7 Constructional requirements as related to performance

4.7.1 General Compliance with the constructional requirement on components shall be checked by inspection.

4.7.2 Components If a MEASURING ASSEMBLY has several ranges or scales, all ranges, scales and components shall be unmistakably and unambiguously identified.

4.7.3 Display

4.7.3.1 Quantities of measurement The indicated unit shall be that of the measuring quantity: AIR KERMA STRENGTH , ABSORBED DOSE TO WATER , REFERENCE AIR KERMA RATE , amperes (which can be converted to AIR KERMA STRENGTH ) i.e. Gy m 2 /h, or A respectively, with SI prefix e.g. m or µ.

4.7.3.2 Indication of battery condition Battery-operated MEASURING ASSEMBLIES shall be provided with a low battery indication for any battery voltage below the RATED RANGE .

4.7.3.3 Indication of polarizing voltage failure M EASURING ASSEMBLIES intended for use with WELL – TYPE IONIZATION CHAMBERS shall be provided with a means of indicating if the polarizing voltage does not meet the MANUFACTURER ‘ S requirement for satisfactory operation.

4.7.4 Inserts The MANUFACTURER shall supply inserts for the type of sources for which the WELL – TYPE IONIZATION CHAMBER is to be used. The inserts shall be constructed in a way that the source can be located at the REFERENCE POINT OF A WELL – TYPE IONIZATION CHAMBER to within ±1 mm. The MANUFACTURER shall specify for which types of sources a given insert may be used. NOTE In some calibrations, the insert is an integral part of the calibration arrangement. Use of an alternative insert voids the calibration.

4.7.5 S TABILIZATION TIME The STABILIZATION TIME shall not be greater than 1 5 min.

4.8 Test of components

The preferred procedure for verifying that the performance requirements are met is to test the components separately, in which case:

a) tests on the MEASURING ASSEMBLY shall be carried out using a current or charge source of sufficient characteristics to meet the objective of the test;

b) tests on the WELL – TYPE IONIZATION CHAMBER shall be performed using a MEASURING ASSEMBLY with sufficient characteristics to meet the objective of the test.

Some tests should be carried out using the complete WELL – TYPE CHAMBER SYSTEM . In particular, this is the preferred method for investigating the effects of radio-frequency electromagnetic fields and electrostatic discharges on a cable-connected WELL – TYPE IONIZATION CHAMBER supplied with a MEASURING ASSEMBLY as a system. Some tests performed with the whole system cannot give information as to whether the origin of a VARIATION lies in the CHAMBER ASSEMBLY or in the MEASURING ASSEMBLY (e.g. LEAKAGE CURRENT and ZERO DRIFT ). If a complete system is tested and the relevant INFLUENCE QUANTITY affects both parts, the quadrate sum of the separate LIMITS OF VARIATION may be taken as an overall LIMIT OF VARIATION .

When a WELL – TYPE IONIZATION CHAMBER and a MEASURING ASSEMBLY are tested separately, but supplied as a system, the two components shall be connected and the combined equipment shall have a measured overall RESPONSE within ±0,5 % of the overall RESPONSE calculated from the RESPONSES of the separate assemblies.

5 Limits of performance characteristics

5.1 Position of source in insert and repeatability

Repetitive positioning of the source at the REFERENCE POINT OF A WELL – TYPE CHAMBER shall give a standard deviation of the readings of 1 % or less.