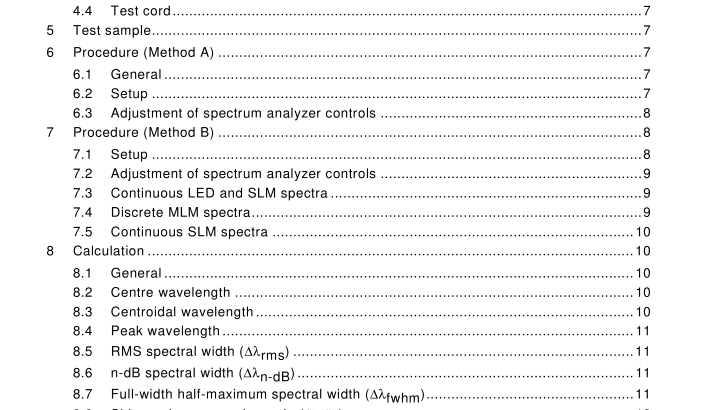

IEC 61280-1-3:2010 pdf download – Fibre optic communication subsystem test procedures – Part 1-3: General communication subsystems – Central wavelength and spectral width measurement

4.4 Test cord Unless otherwise specified, the physical and optical properties of the test cords shall match to the cable plant with which the equipment is intended to operate. The cords shall be 2 m to 5 m long, and shall contain fibres with coatings which remove cladding light. Appropriate connectors shall be used. Single-mode cords shall be deployed with two 90 mm diameter loops or otherwise assure rejection of cladding modes. If the equipment is intended for multimode operation and the intended cable plant is unknown, the fibre size shall be 50/1 25 µm.

5 Test sample The test sample shall be a specified fibre optic subsystem, transmitter, or light source. The system inputs and outputs shall be those normally seen by the user. The spectral width parameters are typically used for characterizing MLM and LED transmitters. The width of MTM and SLM lasers without modulation are normally too narrow to measure with the dispersive spectral instruments used with this method. Modulated SLM transmitters have broadened linewidths for high data rates (above about 2,5 Gb/s) and due to chirp that may be measurable by this method. WARNING – Exercise care to avoid possible eye damage from looking into the end of an energized fibre from any light source. Most importantly, avoid looking into any energized fibre using any type of magnification device. The requirements in IEC 60825-1 shall be followed.

6 Procedure (Method A)

6.1 General Method A is designed for the use of typical commercial optical spectrum analyzer instruments that allow quick measurement of spectra with 1 000 wavelength samples or more, and allows for the analysis of such spectra based on all of the samples rather than selecting for example only the samples at the peaks of mode wavelengths. The previous method using a smaller number of discrete wavelength points is included in Clause 7 as Method B, for compatibility with the first edition of this standard. Method A has the advantage of easier simpler automated analysis and better representation of complex but narrow spectra, such as multitransverse-mode vertical cavity surface emitting lasers (VCSELs). Due to its convenience and prevalence in the industry, Method A is considered the reference test method.

6.2 Setup

6.2.1 Use appropriate handling procedures to prevent damage from electrostatic discharge (ESD), which can cause opto-electronic devices to fail.

6.2.2 With the exception of ambient temperature, standard ambient conditions shall be used, unless otherwise specified. The ambient or reference point temperature shall be 23 °C ± 2 °C, unless otherwise specified.

6.2.3 Unless otherwise specified, apply a modulated input signal to the optical source. Allow sufficient time (per manufacturer’s recommendation or as specified in the detail specification) for the optical source/transmitter to reach a steady-state temperature.

6.2.4 Turn the optical spectrum analyzer on, and allow the recommended warm-up and settling time to achieve rated measurement performance level.

6.2.5 Connect the optical output of the optical source under test to the optical input connector of the optical spectrum analyzer. If the transmitter under test does not include isolation from back-reflections, as often the case at 850 nm, these reflections can cause the spectrum to be unstable and should be reduced with high return-loss connections and possibly external isolation or attenuation at the transmitter output.

6.3 Adjustment of spectrum analyzer controls

6.3.1 Using the resolution control, select an appropriate resolution (see 4.1 ). Typically less than 1 /1 0 of the spectral width to be measured, or the finest available resolution bandwidth (0,1 nm or narrower) should be used. Set the number of data points in the acquired signal to be sure to adequately sample the detail of the optical spectrum. Typically, this is set to at least 4 times the sample resolution times the total measured width. For example, a 1 0 nm measurement span, using 0,1 nm resolution, requires a minimum of 400 points in the measurement (4 × (total span)/resolution).