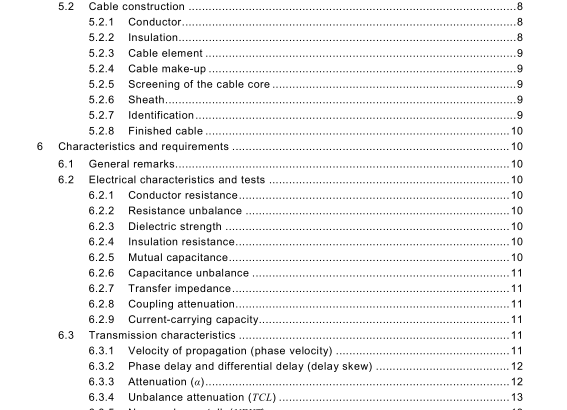

IEC 61156-5:2009 pdf download – Multicore and symmetrical pair/quad cables for digital communications – Part 5: Symmetrical pair/quad cables with transmission characteristics up to 1 000 MHz-horizontal floor wiring – Sectional specification

IEC 62153-4-5,Metallic communication cables test methods – Part 4-5: Electromagneticcompatibility(EMC) -Coupling or screening attenuation – Absorbing clamp method

IEC 62153-4-9,Metallic communication cable test methods – Part 4-9: Electromagneticcompatibility(EMC) – Coupling attenuation of screened balanced cables, triaxial method

3Terms and definitions

For the purposes of this document, the terms and definitions defined in lEC 61156-1 apply.

4lnstallation considerations

4.1General remarks

lnstallation considerations are defined in Clause 4 of lEC 61156-1.

4.2Bending radius of installed cable.

The bending radius of the installed cable shall not be less than 4 times the outside diameterof the cable.

4.3Climatic conditions

Under static conditions,the cables shall operate in the temperature range from -40 *C to+60“C. The conductor and cable temperature dependence is specified for screened andunscreened cables and should be taken into account for the design of an actual cablingsystem.

Other temperature ranges may be specified in the relevant detail specification.

5 Materials and cable construction

5.1General remarks

The choice of materials and cable construction shall be suitable for the intended applicationand installation of the cable.Particular care shall be taken to meet any requirements for EMCand fire performance (such as burning properties,smoke generation,evolution of halogengas, etc.).

5.2Cable construction

The cable construction shall be in accordance with the details and dimensions given in therelevant detail specification.

5.2.1Conductor

The conductor shall be a solid annealed copper conductor,in accordance with 5.2.1 ofIEC 61156-1 and should have a nominal diameter between 0,4 mm and 0,65 mm.A conductordiameter of up to 0,8 mm may be used.

5.2.2 lnsulation

The conductor shall be insulated with a suitable material.Examples of suitable materials are:- polyolefin;

-fluoropolymer;

– low-smoke zero-halogen thermoplastic material.

The diameter of the insulated conductor shall be indicated in the relevant detail specification.

5.2.3Cable element

The cable element shall be a twisted pair or quad.5.2.3.1 Screening of the cable element

When required,the screen for the cable element shall be in accordance with 5.2.3.2 oflEC 61156-1.

5.2.4Cable make-up

A spacer may be used to separate the cable elements. The cable elements,includingspacers, shall be assembled to form the cable core.

The core of the cable may be wrapped with a protective layer of non-hygroscopic and non-wicking material.

5.2.5Screening of the cable core

When required by the relevant detail specification, a screen for the cable core shall beprovided.

The screen shall be in accordance with 5.2.5 of IEC 61156-1.5.2.6Sheath

The sheath material shall consist of a suitable material.

Examples of suitable materials are:

– polyolefin;

-PVc;

-fluoropolymer;

– low-smoke zero-halogen thermoplastic material.

The sheath shall be continuous,having a thickness as uniform as possible.A non-metallicripcord may be provided. When provided,the ripcord shall be non-hygroscopic and non-wicking.

The colour of the sheath is not specified but should be specified in the relevant detailspecification.

5.2.7 ldentification

Each length of cable shall be identified as to the supplier,and when required, a traceabilitycode, using one of the following methods:

a) appropriately coloured threads or tapes;