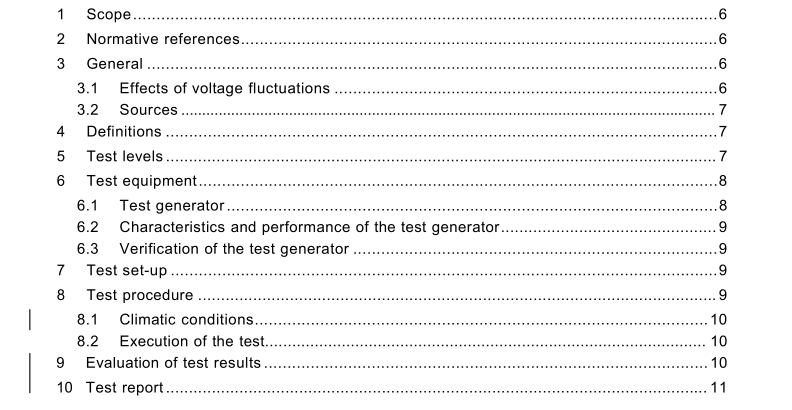

IEC 61000-4-14:2009 pdf download – Electromagnetic compatibility (EMC) – Part 4-14: Testing and measurement techniques – Voltage fluctuation immunity test for equipment with input current not exceeding 16 A per phase

This part of lEC 61000 is a basic electromagnetic compatibility (EMC) publication. lt considersimmunity tests for electrical and/or electronic equipment in their electromagnetic environment.Only conducted phenomena are considered,including immunity tests for equipment connectedto public and industrial power supply networks.

This part aims to establish a reference for evaluating the immunity of electric and electronicequipment when subjected to positive and negative low amplitude voltage fluctuations.

The voltage fluctuations considered by this standard do not include flicker,which is aphysiological phenomenon due to lighting luminance fluctuations.

This standard applies to electrical and/or electronic equipment that have a rated input currentup to 16 A per phase. It does not apply to electrical andlor electronic equipment connected tod.c. or a.c. 400 Hz distribution networks.Tests concerning these networks will be covered byother IEC standards.

The immunity test levels required for a specific electromagnetic environment,together with theperformance criteria,are indicated in the product,product family or generic standards asapplicable.However,most product groups do not have a history of being susceptible to voltagefluctuations.Consequently, testing for these phenomena is often not required.

Normative references

The following referenced documents are indispensable for the application of this document. Fordated references,only the edition cited applies. For undated references, the latest edition ofthe referenced document (including any amendments) applies.

IEC 60050(161),International Electrotechnical Vocabulary (IEV) – Chapter 161: Electro-magnetic compatibility

IEC 60068-1,Environmental testing – Part 1: General and guidance

IEC 61000-2-4,Electromagnetic compatibility(EMC) – Part 2: Environment – Section 4:Compatibility levels in industrial plants for low-frequency conducted disturbances

3General

3.1 Effects of voltage fluctuations

Electrical and electronic equipment may be affected by voltage fluctuations.Examples of theseeffects include the following:

degradation of performances in equipment using storage devices (e.g. capacitors);- loss of function in control systems;

– instability of internal voltages and currents in equipment;- increased ripple.

3.2Sources

There is a significant number of domestic appliances in the low-voltage network.However,fluctuations caused by these appliances are not generally significant.

Fluctuations are mainly produced by

a) continuously but randomly varying large loads such as:

1) resistance welding machines;

2) rolling mills;

3) large motors with varying loads;

4) arc furnaces;

5) arc welding plant;

b) single onloff switching of loads (e.g. motors);

c) step voltage changes (due to tap voltage regulators of transformers).

These industrially produced fluctuations can affect a large number of consumers. Suchequipment operates continuously or infrequently. The public supply network impedance haswide variations, consequently the transmission of the disturbances will be different for differentnetworks.

4Definitions

For the purpose of this part of lEC 61000, the following definitions and terms apply. They areapplicable only to the field of voltage fluctuations;not all of them areincluded inlEC 60050(161).

4.1

immunity

ability of a device,equipment or system to perform without degradation of performance in thepresence of an electromagnetic disturbance [IEV 161-01-20]

4.2

voltage fluctuations

series of voltage changes or a cyclic variation of the voltage envelope [IEV 161-08-05]

6.3 Verification of the test generator

Test generators with different output power capabilities may be used.

The test generator shall be verified that it complies with the characteristics and specifications

listed in Table 2.

Performance of the test generator shall be verified with a resistive load drawing an r.m.s.current of no more than the output capability of the generator. For example, a 230 V/1 6 A generator shall be verified with a 1 4,3 ∧ load.

In addition, the generator’s output current capability shall be verified as being able to provide a crest factor of at least 3 when U n is applied to a single phase load drawing an r.m.s. current of no more than the output capability of the generator. Each output phase of the generator shall be verified in turn. An example of a suitable 230 V/1 6 A verification load is given in Figure 4.

7 Test set-up

Figure 3 shows the test configuration for mains supply simulation.

Waveform generators and power amplifiers may be used.

Tests on three-phase EUT are carried out using three synchronised generators.

8 Test procedure

Before starting the test of a given equipment, a test plan shall be prepared.

It is recommended that the test plan include the following:

– description of the EUT;

– information on possible connections (plugs, terminals, etc.) and corresponding cables and peripherals;

– input power port of the EUT;

– representative operational modes of the EUT for the test;