IEC 60851-2:2009 pdf download – Winding wires – Test methods – Part 2: Determination of dimensions

3.1.2Bunched wire

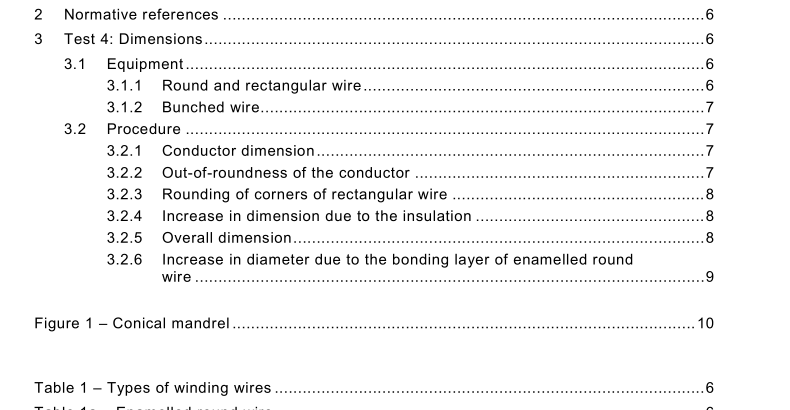

The measurement shall be made with a polished conical mandrel having dimensions asshown in Figure 1.

3.2Procedure

3.2.1 Conductor dimension3.2.1.1 Round wire

NOTE See Table 2.

3.2.1.1.1 Nominal conductor diameter over 0,063 mm and up to andincluding 0,200 mm

From a straight piece of wire the insulation shall be removed at three places,1 m apart, byany method that does not damage the conductor.One measurement shall be made at thesethree places.

The three single values shall be reported.The mean value represents the conductor diameter.3.2.1.1.2Nominal conductor diameter over 0,200 mm

From a straight piece of wire, the insulation shall be removed by any method that does notdamage the conductor.Three measurements of the bare conductor diameter shall be made atpoints evenly distributed around the circumference of the conductor.

The three single values shall be reported.The mean value represents the conductor diameter.3.2.1.2Rectangular wire

The insulation shall be removed at the three places used for measurements in 3.2.5.2 by anymethod that does not damage the conductor. At each place one measurement of the twodimensions of the conductor shall be made.

The three single values shall be reported for each dimension of the conductor.The meanrepresents the conductor width or the conductor thickness respectively.

3.2.2out-of-roundness of the conductor

Out-of-roundness is the maximum value of the difference between the three readings ifmeasured in accordance with 3.2.1.1.1, or the three readings of the conductor diameter at thecross-section if measured in accordance with 3.2.1.1.2.The out-of-roundness shall bereported.

3.2.3Rounding of corners of rectangular wire

For the purpose of this test, a cross-section of the wire shall be prepared and then examinedunder a sufficient magnification.

Three straight pieces of wire shall be cast in a suitable resinous compound that will not affectthe insulation.After curing, the colour of the resinous compound shall contrast with the colourof the insulation.

The specimen consisting of the three pieces of wire embedded in the cured resinouscompound shall be cut at right angles to the length of the wire pieces, and the cross-sectionshali be carefully ground and polished by suitable means. The polished surface shall beexamined under a magnification which allows a correct judgement of the rounding of corners.

lt shall be reported how the arc merges into the flat surface of the conductor. Any sharp,rough and projecting edges shall also be reported.

3.2.4Increase in dimension due to the insulation3.2.4.1General

The increase in dimension due to the insulation is the difference between the overalldimension and the conductor dimension.

3.2.4.2Round wire

The measurement shall be made in accordance with 3.2.1.1 and 3.2.5.1.The differencebetween the overall diameter and the conductor diameter shall be reported as the increasein diameter.

3.2.4.3Rectangular wire

The measurement shall be made in accordance with 3.2.1.2 and 3.2.5.2. The differencebetween the overall width and the conductor width shall be reported as the increase in width.The difference between the overall thickness and the conductor thickness shall be reported asthe increase in thickness.

3.2.5overall dimension3.2.5.1 Round wire

3.2.5.1.1 Nominal diameter up to and including 0,200 mm

On a straight piece of wire,at three places 1 m apart,one measurement of the overalldiameter shall be made.

The three single values shall be reported.The mean value represents the overall diameter.3.2.5.1.2Nominal conductor diameter over 0,200 mm

On a straight piece of wire,at each of two places 1 m apart,three measurements of theoverall diameter shall be made at points evenly distributed around the circumference of thewire.