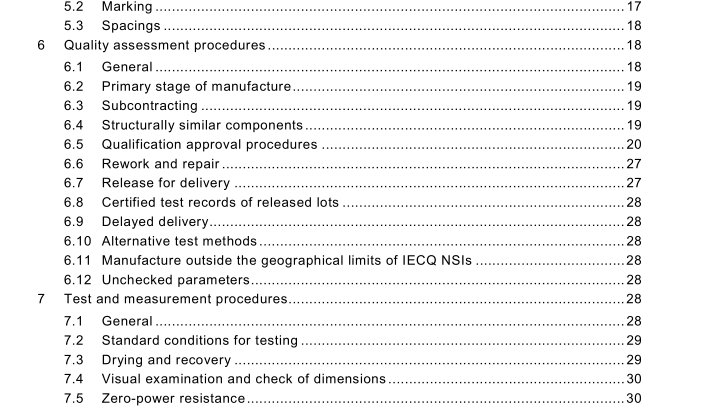

IEC 60738-1:2009 pdf download – Thermistors – Directly heated positive temperature coefficient – Part 1: Generic specification

When these documents are used outside such quality assessment systems for purposes such as design proving or type testing, the procedures and requirements of 6.5.1 and 6.5.3b) may be used, but, if used, the tests and parts of tests shall be applied in the order given in the test schedules. Before thermistors can be qualified according to the procedures of this subclause, the manufacturer shall obtain the approval of his organization in accordance with the provisions of IEC QC 001 002-3. The method for the approval of thermistors of assessed quality given in6.5 is qualification approval according to the provisions of Clause 3 of IEC QC 001 002-3.

6.1 .1 Applicability of qualification approval Qualification approval is appropriate for a standard range of thermistors manufactured to similar design and production processes and conforming to a published detail specification. The programme of tests defined in the detail specification for the appropriate assessment and performance levels applies directly to the subfamily of thermistors to be qualified, as prescribed in 6.5 and the relevant blank detail specification.

6.2 Primary stage of manufacture The primary stage of manufacture is defined as the initial mixing process of the ingredients.

6.3 Subcontracting If subcontracting of the primary stage of manufacture and/or subsequent stages is employed it shall be in accordance with 4.2.2 of IEC QC 001 002-3. The blank detail specification may restrict subcontracting in accordance with 4.2.2.2 of IEC QC 001 002-3. 6.4 Structurally similar components Thermistors may be grouped as structurally similar for the purpose of forming inspection lots provided that the following requirements are met.

– They shall be produced by one manufacturer on one site using essentially the same design, materials, processes and methods.

–The sample taken shall be determined from the total lot size of the grouped devices.

– Structurally similar devices should preferably be included in one detail specification but the details of all claims to structural similarity shall be declared in the qualification approval test reports.

6.4.1 For electrical tests, devices having the same electrical characteristics may be grouped provided that the element determining the characteristics is similar for all the devices concerned.

6.4.2 For environmental tests, devices having the same encapsulation, basic internal structure and finishing processes may be grouped.

6.4.3 For visual inspection (except marking), devices may be grouped if they have been made on the same production line, have the same dimensions, encapsulation and external finish.

This grouping may also be used for robustness of terminations and soldering tests where it is convenient to group devices with different internal structures.

6.4.4 For endurance tests, thermistors may be grouped if they have been made on the same production line using the same design and differing only in electrical characteristics. If it can be shown that one type from the group is more heavily stressed than the others then tests on this type may be accepted for the remaining members of the group.

6.5 Qualification approval procedures

6.5.1 Eligibility for qualification approval

The manufacturer shall comply with 3.1 .1 of IEC QC 001 002-3.

6.5.2 Application for qualification approval

The manufacturer shall comply with 3.1 .3 of IEC QC 001 002-3.

6.5.3 Test procedure for qualification approval

One of the two following procedures shall be followed.

a) The manufacturer shall produce test evidence of conformance to the specification requirements on three inspection lots for lot-by-lot inspection taken in as short a time as possible and one lot for periodic inspection. No major changes in the manufacturing process shall be made in the period during which the inspection lots are taken. Samples shall be taken from the lots in accordance with IEC 6041 0 (see Annex A). Normal inspection shall be used, but when the sample size would give acceptance on zero non- conformances, additional specimens shall be taken to meet the sample size requirements to give acceptance on one non-conforming item. b) The manufacturer shall produce test evidence to show conformance to the specification requirements on one of the fixed sample size test schedules given in 6.5.4. The specimens taken to form the sample shall be selected at random from current production or as agreed with the National Supervising Inspectorate (NSI).