IEC 60539-2:2010 pdf download – Directly heated negative temperature coefficient thermistors – Part 2: Sectional specification – Surface mount negative temperature coefficient thermistors

1 General1.1Scope

This part of lIEC 60539 is applicable to surface mount directly heated negative temperaturecoefficient thermistors,typically made from transition metal oxide materials withsemiconducting properties. These thermistors have metallized connecting pads or solderingstrips and are intended to be mounted directly on to substrates for hybrid circuits or on toprinted boards.

1.2Normative references

The following referenced documents are indispensable for the application of this document.For dated references, only the edition cited applies. For undated references, the latest editionof the referenced document (including any amendments) applies.

IEC 60068-2-2:1974,Environmental testing – Part 2:Tests -Tests B: Dry heatAmendment 1 (1993)

Amendment 2 (1994)

IEC 60068-2-14:1984,Environmental testing – Part 2: Tests -Test N: Change of temperatureAmendment 1 (1986)

IEC 60068-2-30:1980,Environmental testing – Part 2: Tests – Test Db and guidance: Dampheat, cyclic (12+12-hour cycle)

Amendment 1 (1985)

IEC 60068-2-58:1999 2004, Environmental testing – Part 2-58:Tests -Test Td:Test methodsfor solderability,resistance to dissolution of metallization and to soldering heat of surfacemounting devices (SMD)

lEC 60068-2-78: Environmental testing – Part 2-78:Tests – Test Cab: Damp heat,steadystate

IEC 60410:1973,Sampling plans and procedures for inspection by attributes

IEC 60539-1:2002,Directly heated negative temperature coefficient thermistors – Part 1:Generic specification

1.3Information to be given in a detail specification

Detail specifications shall be derived from the relevant blank detail specification.

Detail specifications shall not specify requirements inferior to those of the generic, sectionalor blank detail specification. When more severe requirements are included,they shall belisted in 1.9 of the detail specification and indicated in the test schedules, for example, by anasterisk.

NOTE The information given in 1.3.1 may for convenience, be presented in tabular form.

The following information shall be given in each detail specification and the values quotedshall preferably be selected from those given in the appropriate clause of this sectionalspecification.

1.3.1Outline drawing and dimensions

There shall be an illustration of the thermistor as an aid to easy recognition and forcomparison with others. Dimensions and their associated tolerances,which affect inter-changeability and mounting,shall be given in the detail specification. All dimensions shallpreferably be stated in millimetres; however,when the original dimensions are given ininches, the converted metric dimensions in millimetres shall be added.

Normally,the numerical values shall be given for the length,width and height of the body.When necessary, for example when a number of items are covered by a detail specification,the dimensions and their associated tolerances shall be placed in a table below the drawing.

When the configuration is other than described above, the detail specification shall state suchdimensional information as will adequately describe the thermistor.

1.3.2Mounting

The detail specification shall give guidance on methods of mounting for normal use. Mountingfor test and measurement purposes (when required) shall be in accordance with 4.27 ofIEC 60539-1.

1.3.3 Ratings and characteristics1.3.3.1 Particular characteristics

Additional characteristics may be listed when they are considered necessary to specify thecomponent adequately for design and application purposes.

1.3.3.2 Marking

See 2.4 of lEC 60539-1.1.4TerminologySee

2.2 of IEC 60539-1.

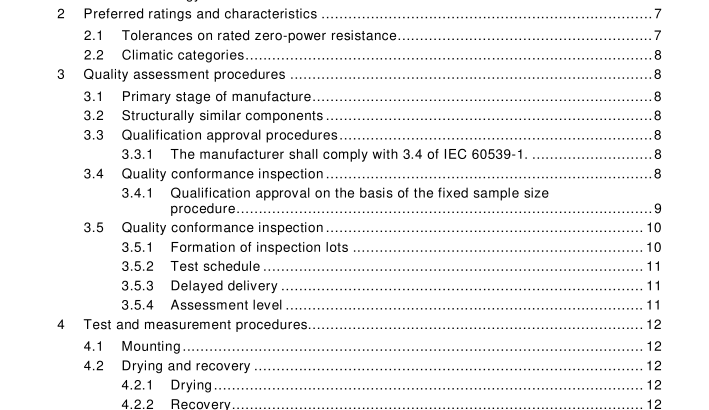

2Preferred ratings and characteristics

2.1Tolerances on rated zero-power resistance

3 Quality assessment procedures

3.1 Primary stage of manufacture

The primary stage of manufacture is defined as the initial mixing process of ingredients.

3.2Structurally similar components

Surface mount thermistors may be grouped as structurally similar for the purpose of forminginspection lots provided that the requirements of 3.1 of lEC 60539-1 are met,with thefollowing addition.

For the shear test and the substrate bending test, devices may be grouped if they have beenmade on the same production line, have the same dimensions’, internal structure and externalfinish.

3.3Qualification approval procedures

3.3.1 The manufacturer shall comply with 3.4 of IEC 60539-1.3.4Quality conformance inspection

Blank detail specifications associated with this specification shall prescribe the test schedulefor quality conformance inspection.

This schedule shall also specify the grouping, sampling and periodicity for the lot-by-lot andperiodic inspection.

Inspection levels and sampling plans shall be selected from those given in lEC 60410.lf required, more then one test schedule may be specified.