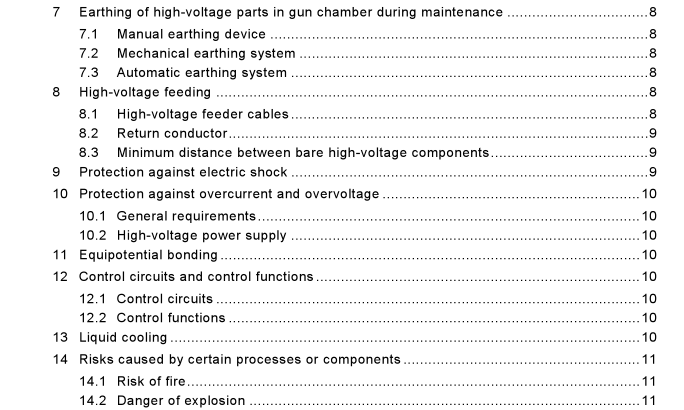

IEC 60519-7:2008 pdf download – Safety in electroheat installations – Part 7: Particular requirements for installations with electron guns

7 Earthing of high-voltage parts in gun chamber during maintenance

7.1 Manual earthing device After switching off the high-voltage supply and gaining access by opening the door of the electron gun chamber or the housing of the electron gun, a portable earthing device of an approved design shall be used to remove any remaining charge before touching parts, which are normally live during operation. The highly flexible earth conductor of the portable earthing device shall be permanently fixed to its earthing point. This earth connection point shall be visible for easy checking by the operator and be clearly and durably marked.

7.2 Mechanical earthing system Alternatively, a mechanically self-acting earthing mechanism that is activated by the mechanical action of opening the gun chamber may be installed, provided that the proper function of this self-acting mechanism can be easily checked by eyesight from a safe distance.

7.3 Automatic earthing system Alternatively, an automatically operating earthing mechanism may be installed under the following conditions:

a) the mechanism is automatically activated when the gun operation is stopped;

b) the proper functioning of the automatic mechanism is detected by a fail-proof automatic detection system;

c) a signal visible to personnel opening the gun chamber indicates proper functioning of the automatic earthing system;

d) an electro-mechanic lock of approved design disables opening of the gun chamber before the proper functioning of the earthing device has been positively detected. Also, in the immediate vicinity of the high-voltage supply(ies), portable earthing devices shall be installed so as to be clearly visible.

8 High-voltage feeding

8.1 High-voltage feeder cables The high-voltage feeder cables shall be adequately insulated and efficiently protected against mechanical damage. Shielded cables shall be used for the high-voltage feeders or the feeder cables shall be installed inside conductive conduits or flexible hoses. Cable shields, conduits or flexible hoses shall be connected to the equipotential bonding. When high-voltage feeder cables are laid inside conduits or flexible hoses, other cables shall not be included, except a return conductor. Each electron gun shall have its own conduit or flexible hose. If the high-voltage feeder cable runs inside a conduit or flexible hose, the conduit or flexible hose shall extend into the high-voltage terminal connection compartment.

High-voltage feeder cables and low-voltage cables may run together inside cable trenches or cable troughs providing the high-voltage feeder cables are protected mechanically and electrically.

The cable trenches or troughs are not considered as protection. 8.2 Return conductor Each electron gun shall have its own return conductor to carry the beam current back to the high-voltage power supply in a specified way. The cross-sectional area of this conductor shall be of a size corresponding to the current of the gun but not less than 6 mm 2 copper. The return conductor shall be installed with flexible and insulated cable.

The return conductor shall be connected to earth potential at the termination point near the workpiece or the electron gun. To enable a defined return current path, the return conductor shall not be earthed at the high- voltage power supply, but the voltage between the termination point and earth shall be limited by reliable means. If the return conductor is also directly connected to earth at the high- voltage supply, EMC requirements and grounding shall be taken under special care. If, for special guns, a conductor of less than 6 mm 2 copper is employed, it shall be installed with special care, be mechanically protected and be at least of the size of the feeder conductors. The voltage drop along the return conductor shall not exceed 1 ,5 V at rated current. Return conductors between electron guns and the high-voltage power supply shall be installed together with the feeders.

NOTE 1 Each installation should have at least two return conductors so that safety is maintained even if one fails. The exact arrangement of return conductors depends on the quality of the electrical interconnections of the electron gun chamber and the vacuum chamber as well as on the number of electron guns.

NOTE 2 In an installation with electron guns, the return current flows through the chamber and the framework of the installation in the direct surroundings of the electron gun.