IEC 60432-3:2008 pdf download – Incandescent lamps – Safety specifications – Part 3: Tungsten-halogen lamps (non-vehicle)

3 Assessment

3.1 General This clause specifies the method a manufacturer should use to show that his product conforms to this standard on the basis of whole production assessment, in association with his test records on finished products. This method can also be applied for certification purposes. Subclause

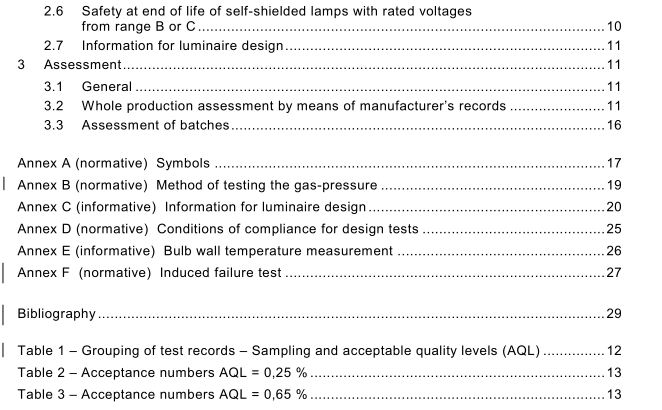

3.2 gives details of assessment by means of the manufacturer’s records. Details of a batch test procedure which can be used to make limited assessment of batches are given in 3.3. Requirements for batch testing are included in order to enable the assessment of batches presumed to contain unsafe lamps. As some safety requirements cannot be checked by batch testing, and as there may be no previous knowledge of the manufacturer’s quality, batch testing cannot be used for certification purposes nor in any way for an approval of the batch. Where a batch is found to be acceptable, a testing agency may only conclude that there is no reason to reject the batch on safety grounds. 3.2 Whole production assessment by means of manufacturer’s records The manufacturer shall show evidence that his products comply with the particular requirements of 3.2.1 .

To this end, the manufacturer shall make available all the results of his product testing pertinent to the requirements of this standard. The test results may be drawn from working records and, as such, may not be immediately available in collated form. The assessment shall be based in general on individual factories, each meeting the acceptance criteria of 3.2.1 . However, a number of factories may be grouped together, providing they are under the same quality management. For certification purposes, one certificate may be issued to cover a nominated group of factories, but the certification authority shall have the right to visit each plant to examine the local relevant records and quality control procedures. For certification purposes, the manufacturer shall declare a list of marks of origin and corresponding lamp families, groups and/or types which are within the scope of this standard and manufactured in a nominated group of factories. The certificate shall be taken to include all lamps so listed made by the manufacturer. Notification of additions or deletions may be made at any time. In presenting the test results, the manufacturer may combine the results of different lamp families, groups and/or types according to column 4 of Table 1 .

The whole production assessment requires that the quality control procedures of a manufacturer shall satisfy recognized quality system requirements for final inspection. Within the framework of a quality assurance system based also on in-process inspection and testing the manufacturer may show compliance with some of the requirements of this standard by means of in-process inspection instead of finished product testing. The manufacturer shall provide sufficient test records with respect to each clause and subclause as indicated in column 5 of Table 1 .

When compliance is assessed after corrective action has been taken in accordance with items a) and b), the test records of these lamp families, groups and/or types which do not comply shall be excluded from the 1 2-month summation for their period of non-compliance. The test results relating to the period of corrective action shall be retained in the records. A manufacturer who has failed to meet the requirements of a clause or subclause where grouping of the test results is permitted shall not be disqualified for the whole of the lamp families, groups and/or types so grouped if he can show by additional testing that the problem is present only in certain families, groups and/or types so grouped. In this case, either these families, groups and/or types are dealt with in accordance with a) and b) as above or they are deleted from the list of families, groups and/or types which the manufacturer may claim are in conformity with the standard.