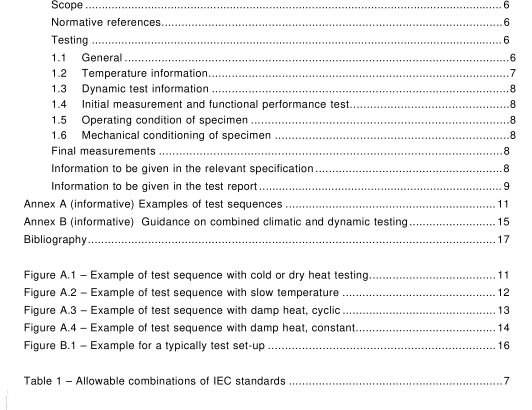

IEC 60068-2-53:2010 pdf download – Environmental testing – Part 2-53: Tests and guidance – Combined climatic (temperature/humidity) and dynamic (vibration/shock) tests

The combinations of environmental conditions should be selected to ensure that electrical and mechanical performances of the specimen are satisfactory under storage, transportation and operational conditions. Certain combinations of possible tests shown in Table 1 may not be practicable. Examples of these include the following:

– full sweep of sinusoidal vibration spectrum not completed during change of temperature or temperature cycling;

– temperature stabilization of dynamic non linear systems, e.g. anti vibration mounts during vibration with change of temperature or temperature cycling;

– full cycle of mixed mode vibration during change of temperature or temperature cycling.

Specimens may be repositioned for shock or vibration along another axis at standard climatic conditions according to IEC 60068-1 , as required by the relevant specification. The dynamic test shall be continued when the required test temperature and humidity has been reached.

3.2 Temperature information If cold or dry heat testing is required, the exposure time shall not commence until all parts of the specimen have reached a temperature within at least 3 K of the working space temperature. For heat-dissipating specimens, the period of exposure shall not begin until the temperature of the specimens changes not more than 1 K within 1 h at the stabilized working space temperature.

The last hour of the temperature-soaking time shall be considered to be the first hour of the exposure period. If a damp heat constant testing is required, the exposure time shall not commence until all parts of the specimen have reached a temperature within at least 3 K of the temperature, and a relative humidity within 3 % of the humidity, within the working space of the test chamber. For heat-dissipating specimens, the period of exposure shall not begin until the temperature of the specimens changes not more than 1 K within 1 h at the stabilized working space temperature. The last hour of the temperature-soaking time shall be considered to be the first hour of the exposure period.

lf the specimen is mounted on shock absorbers,time shall be given for temperaturestabilization of the absorber elements.

3.3Dynamic test information

The relevant specification shall contain dynamic test information.The dynamic testinformation includes following details (see also Clause 5):

a) identification of dynamic test ( such as sinusoidal,random,mixed mode vibration orimpact);

b) severities of dynamic stress;

c)axis and directions of dynamic stress;

d) duration and timing of dynamic stress (see Annex A);

e) IEC 60068-2-47 shall be referred to concerning mounting of specimen;

f) other details specified in the reference standards.

3.4Initial measurement and functional performance test

The specimen shall be submitted to the visual, dimensional, functional and any other checksprescribed by the relevant specification.

3.5Operating condition of specimen

In the case of electrically-operated specimens,the times at which the power supply shall bepowered on or off and the voltage of the power supply within each temperature cycle shall bespecified in the relevant specification.

The times at which other functions such as cooling, heating and various loads are switched onor off shall be stipulated in the relevant specification or controlled by a special type of testequipment.

3.6Mechanical conditioning of specimen

The mechanical conditioning of the specimen per cycle shall preferably be performed in thelast hour of the hot or cold phase,i.e. prior to the changeover to the following limittemperature,or shall be performed in any other combination which can be defined in therelevant specification. lf the specimen is operated by power supply,this shall be connectedfor the duration of the mechanical conditioning.

Final measurements

The specimen shall be submitted to the visual, dimensional and functional checks prescribedby the relevant specification.

The relevant specification shall provide the criteria upon which the acceptance or rejection ofthe specimen is to be based.

5lnformation to be given in the relevant specification

The relevant specification shall contain the following details as far as they are applicable: