IEC 60034-30:2008 pdf download – Rotating electrical machines – Part 30: Efficiency classes of single-speed, three-phase, cage-induction motors (IE-code)

Motors specifically built for operation in explosive environments according to lEC 60079-0 arecovered by this standard. However,as a result of safety requirements and certain designconstraints of explosion proof motors (like increased air-gap,reduced starting current,enhanced sealing and others) some may not be able to achieve higher~efficiencyclassifications.

NOTE 1 Due to the required certification processes additional time and cost may be necessary to achieve thehigher efficiency ratings for some of these motors.

Motors specifically designed

for special requirements of the driven machine (e.g. heavy starting duty, special torque stiffness and/or breakdown torque characteristics,large number ofstartlstop cycles, very low rotor inertia);

for special characteristics of the grid supply (e.g. limited starting current,hightolerances of voltage and/or frequency);

for special ambient conditions (e.g. very high or low ambient temperature; smokeextraction motors,high altitudes of installation),

may not be able to achieve higher efficiency classifications.

NOTE 2 Regulators should consider the above constraints when assigning national minimum energy efficiencyperformance standards (MEPS).

5 Efficiency

5.1 Determination5.1.1General

The efficiency shall be determined at rated output power Py, rated voltage Uy and ratedfrequency fn-

Efficiency and losses shall be determined in accordance with lEC 60034-2-1.

For lE1 (standard efficiency) and motors below standard efficiency, test methods associatedwith low and medium uncertainty are acceptable.The selected test method shall be stated inthe documentation of the motor.

For all higher energy efficiency levels only methods associated with low uncertainty shall beacceptable.

5.1.2Rated voltages, rated frequencies and rated output

Motors rated for an extended voltage tolerance (for example 400 v±10 %) shall be assigneda single rated efficiency and rated efficiency-class (IE-code), i.e. the extended tolerance shallbe disregarded.

Motors with more than one rated voltage/frequencyloutput-power combination may beassigned a rated efficiency and a rated efficiency-class (IE-code) for each ratedvoltage/frequencyloutput combination.

All efficiency values and associated lE-codes shall be available in the product documentation(catalogue or operating instructions).

NOTE For example in Japan the rating combination “200 vI50 Hz – 200 V/60 Hz – 220 V60 Hz” is commonlyused and in Europe the rating combination“380 VI50 Hz – 400 v/50 Hz – 415VI50 Hz – 460 v60O Hz” issometimes used. For these examples there will be three or four efficiency ratings and there may be severaldifferent lE-codes.

Rated voltage/frequency combinations of the same magnetic flux and output-power,forexample 230/40o v (delta/star) or 230/460 v(double-star/star),shall have only one ratedefficiency and efficiency-class (IE-code).

5.1.3Auxiliary devices

Some electric motors covered by this standard may be equipped with auxiliary devices likeshaft seals,external fans,mechanical brakes, back-stops, speed sensors, tacho-generators,etc. in various combinations.

However, as long as these auxiliary devices are not an integral part of the motor construction,the determination of efficiency in ail possible combinations is not practical.Tests for efficiencyof such modified standard motors shall be performed on basic motors without auxiliarydevices installed.

Geared motors and pump motors are often standard motors equipped with shaft seals toprevent ingress of oil or water into the motor.The seals are therefore considered a feature ofthe gearbox or pump and consequently the efficiency of these motors shall be determinedwithout the seals installed.

5.2Rating

Variations in materials,manufacturing processes,and testing result in motor-to-motorefficiency variations for a given motor design; the full-load (rated output) efficiency for a largepopulation of motors of a single design is not a unique value but rather a band of efficiency.Therefore, the rated output energy-efficiency limits given in this standard are nominal.

The efficiency declared by the manufacturer on the rating plate (rated efficiency) shall begreater or equal to the nominal efficiency as defined in this standard (according to theefficiency class (lE-code) on the rating plate).

The full-load efficiency of any individual motor,when tested at rated voltage and frequency,shall not be less than the rated efficiency minus the tolerance on efficiency in accordance withIEC 60034-1.

NOTElt is recommended to report efficiencies at 50 %,75 % and rated output in the product documentation.Forthe purpose of this standard the efficiency at rated output applies.

5.3Classification and marking

5.3.1General

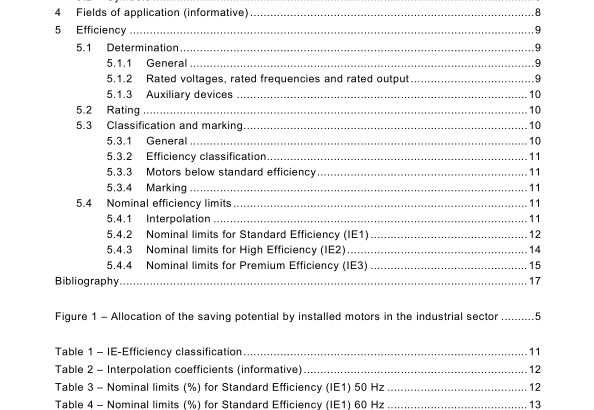

The designation of the energy efficiency class consists of the letters “IE”(short for”International Energy-efficiency Class”), directly followed by a numeral representing theclassification according to Table 1.