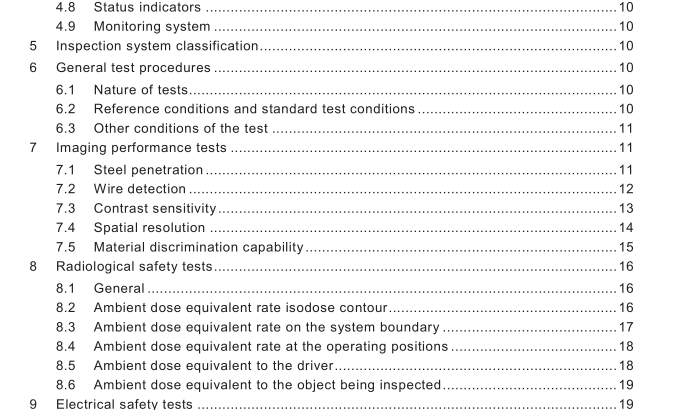

BS IEC 62523:2010 pdf download – Radiation protection instrumentation — Cargo/vehicle radiographic inspection system

4 General characteristics of cargo/vehicle radiographic inspection system

4.1 General The inspection systems are designed to create an image of the inspected object for an operator to detect, locate, and identify contraband hidden in cargo and/or vehicles. Such a system is generally composed of a radiation source(s), detectors, a mechanical and control system, an image processing system, a radiation safety system to protect the operators and the public against radiation, and other auxiliary devices/facilities. The manufacturer shall state power requirements and the warm-up or set-up time of the system.

4.2 Emergency stop devices Inspection systems shall be equipped with emergency stop devices such as emergency buttons, so that the radiation beam can be automatically shut off or the radioactive source can be automatically retracted into its shielding assembly whenever any of these devices is activated. Once any emergency stop device has been activated, the system shall not be able to restart the radiation beam automatically. Manual operation, such as inserting a key on the operator control panel and turning it to the “ON” position, is required to enable the restart of the radiation beam. Emergency stop devices shall be installed at several locations including, but not limited to the operator control panel and in relatively close proximity to the radiation source and the detectors. The emergency stop devices shall work in a fail-safe mode. If an emergency stop device fails, the radiation beam shall be shut off, and a failure status shall be indicated on the control panel. For a gamma-ray system, the radioactive source shutter shall be automatically closed or the source shall be automatically retracted into its shielding assembly, in case of power failure.

4.3 Software The system shall be able to process and display, save, backup and restore the digital radiographic images of the inspected objects and other relevant inspection data, such as container numbers, inspection date and cargo contents.

4.4 Markings

Markings shall be readable and permanently attached, including at least:

• manufacturer name;

• model number;

• unique serial number;

• function designation for control, switches, adjustments;

• radiation source and energy;

• ionizing radiation warning symbol;

• other safety warnings.

4.5 Ambient dose equivalent rate isodose contour

The manufacturer should provide an isodose contour of the ambient dose equivalent rate around the source when the inspection system is operating.

This isodose contour is provided for reference purposes only. It may change substantially based upon the motion of the system and the object placed in the beam.

4.6 Radioactive sources Radioactive sources shall be properly shielded and protected from unauthorized access. The transportation and labelling of the radioactive sources shall comply with national and/or international requirements (e.g., IAEA No.TS-R-1 and IAEA No.RS-G-1 .1 0). Provisions should be made for routine leak testing of the radioactive sources, in accordance with ISO 9978:1 992 in order to minimize the radiation exposure to the operator.

4.7 Safety interlocks Safety interlocks shall be installed to prevent people from being accidentally exposed. The radiation beam can only be turned on after all the safety interlocks are in the “ON” position. If the status of any interlocks changes during operation, the radiation beam shall be terminated or shuttered. The safety interlocks shall be designed to work in fail safe mode. The safety interlocks shall provide an interface to link additional safety devices.

4.8 Status indicators Status indicators shall be installed to provide audible and visual warning signals to warn people of the danger of radiation exposure. These warning signals shall be started at least 5 s before the beam is turned on and remain on during the scan until the radiation beam is turned off. The configuration of status indicators shall comply with local regulations. Ionizing radiation warning symbols or placards shall be placed along the boundary of the controlled area and the supervised area. 4.9 Monitoring system A video monitoring system shall be provided for the operator to observe the controlled area and the supervised area.