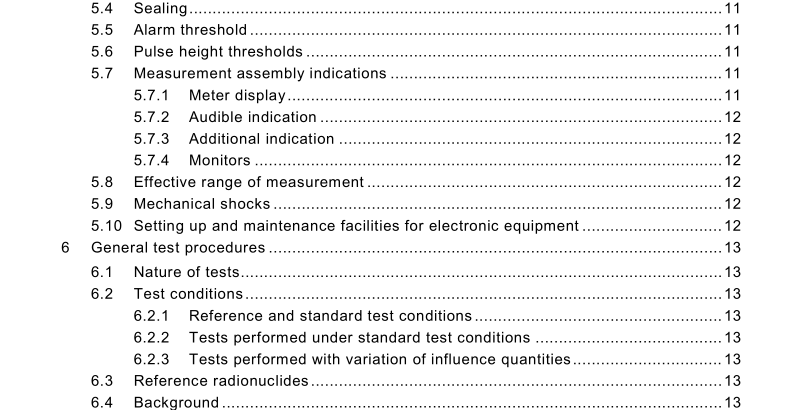

BS IEC 62363:2008 pdf download – Radiation protection instrumentation — Portable photon contamination meters and monitors

5.7.2 Audible indication An audible indication of count rate shall be provided. There shall be a facility for muting this indication. Where the equipment has been designed for use where noise levels could be high, provision shall be made for the use of a head set.

5.7.3 Additional indication Indication shall be given of operational conditions in which the indication is not correct (within the specifications of this standard), for example low battery or detector failure.

5.7.4 Monitors All the characteristics described in 9 9 H 5.7.1 , 1 0 0 H 5.7.2 and 1 0 1 H 5.7.3 are also required for monitors. In addition to the audible indication of count rate (or activity) above, there shall be either an audible indication of contamination above a certain preset value or visual indication. Although the audible indication may be produced by the same transducer as the indication of count rate, it shall be distinctly different from this indication.

5.8 Effective range of measurement For logarithmically scaled assemblies, the effective range of measurement shall be from below one third of the least significant decade to full scale. For digitally scaled assemblies, the effective range of measurement shall be from the start of the second least significant digit to the maximum of the rated range of measurement. The manufacturer shall state the effective range of measurement of each scale range. For assemblies with more than one scale range, the effective range of measurement for each range shall overlap. For assemblies with digital and scientific display (e.g. x,y × 1 0 ±2 ) the mantissa shall have at least two digits (for instance 1 ,0 to 9,9) and the manufacturer shall define the effective range of measurement (for instance 1 ,0 × 1 0 –2 to 9,9 × 1 0 4 with units counts·s –1 ). For the purposes of this standard, assemblies using this type of display shall conform to the requirements of digital scaled assemblies. Consideration should be given to providing the capability for the determination of low count rates, possibly using an integration facility.

5.9 Mechanical shocks Portable assemblies shall be able to withstand without damage mechanical shocks from all directions involving a peak acceleration of 300 m·s –2 for a time interval of 1 8 ms, the shape of the shock being semi-sinusoidal (see IEC 60068-2-27).

5.1 0 Setting up and maintenance facilities for electronic equipment In addition to an adequate instruction and maintenance manual, all assemblies shall be provided with sufficient easily accessible test points to facilitate setting up and fault location, together with, where necessary, maintenance aids such as extension printed wiring boards, extension leads and special maintenance tools. Facilities shall be provided to prevent the unauthorised access to all the set-up functions of the equipment.

6 General test procedures

6.1 Nature of tests Qualification tests are performed in order to verify that the requirements of a specification are fulfilled (see 3.25). Qualification tests are subdivided into type tests and routine tests (see 3.26 and 3.27). All tests enumerated in the following clauses are to be considered as “type tests”, with the exception of the test described in 1 0 2 H 8.3.4. Some of these tests may, by agreement between the manufacturer and purchaser, be considered to be acceptance tests (see 3.28). Unless otherwise specified, the requirements corresponding to the tests shall be met over the whole effective range of measurement of the instrument. Since the configuration of the measurement assembly is critical to the performance characteristics of the instrument, then both the measurement and the detection assemblies shall be tested together as a single unit. Tests on measurement assemblies are described fully in IEC 60325.

6.2 Test conditions 6.2.1 Reference and standard test conditions Reference conditions are given in the second column of Table 1 . Except where otherwise specified, the tests in this standard shall be carried out under the standard test conditions given in the third column of Table 1 .