AS IEC 62308:2008 pdf download – Equipment reliability—Reliability assessment methods

This only holds when λ is constant. Another useful but problematic quantity is the total accumulated number of product-hours, sometimes denoted by T*. Under the assumption of constant failure rate there is no difference from a statistical point of view between accumulating 1 000 000 h by one product, or 1 h by 1 000 000 products. In either case a point estimate of the population failure rate if there is one failure would be 1 0 -6 failures per product-hour. The parameter λ being independent of time is referred to as the constant failure rate. A constant failure rate has many useful properties, one of which is that the mean value of the distribution of the product’s time to failure is 1 /λ. For non-repaired items (components), this mean value represents the statistically expected average length of time until product failure, commonly called the mean life or MTTF.

This means that 63 % of the items can be expected to fail from time 0 until MTTF and 37 % after the MTTF. Another useful property of the constant failure rate is that it can be estimated from a population as the fractional decrease in the number of surviving items per unit time. However, it should be noted that the exponential distribution is the only distribution for which the failure rate is a constant and that the mean life is not 1 /λ(t) when the failure rate is not constant. For repaired items, MTTF is sometimes misunderstood to be the life of the product rather than the reciprocal of the constant failure rate. If a product has an MTTF of 1 000 000 h, it does not mean that the product will last that long (longer than the average human lifetime).

Rather, it means that, on average, one of the products will fail for every 1 000 000 product-hours of operation, i.e. if there are 1 000 000 products in the field on average, one of them will fail in 1 h on average. In this case, if product failures are truly exponentially distributed, then on average 63 % of the products will have failed after 1 000 000 h of operation. Products with truly exponentially distributed failures over their entire lifetime almost never occur in practice, but a constant failure rate and MTTF may in some cases be a good approximation to product failure behaviour.

There are several equivalent ways of expressing the constant rate measures in Table 1 . For example, a constant failure rate of 1 % per year is equivalent to 1 ,1 1 0 -6 h -1 , 1 1 00 FITs, 0,01 failures per unit per year, 1 ,1 failures per million hours, and 1 0 failures per 1 000 products per year (assuming replacement, 9,95 failures per 1 000 products per year without replacement).

6.2.3 Repaired and non-repaired item concepts Specifying a single value, such as MTTF, is not sufficient for a product that exhibits a time- dependent failure rate. This standard considers similarity analysis for the constant failure rate case as well as for non-constant failure rate. IEC 61 649, IEC 61 71 0 and IEC 60300-3-5 give details on statistical methods for non-constant failure rate, including Weibull analysis. Situations may also occur when repaired items, which are restored to functionality after failure, are not repaired to a ‘good-as-new’ condition and so exhibit a non-constant failure intensity. IEC 60300-3-5 provides guidance on non-constant failure rate and non-constant failure intensity. MTTF should be used in case of non-repairable items and MTBF should be used in case of repairable items. Generally it is recommended to state the failure probability, F(t), of the item instead of stating MTBF or MTTR; however, if MTTF is used it should be used for non-repaired items and MTBF used for repaired items.

6.2.4 Methods for estimating reliability

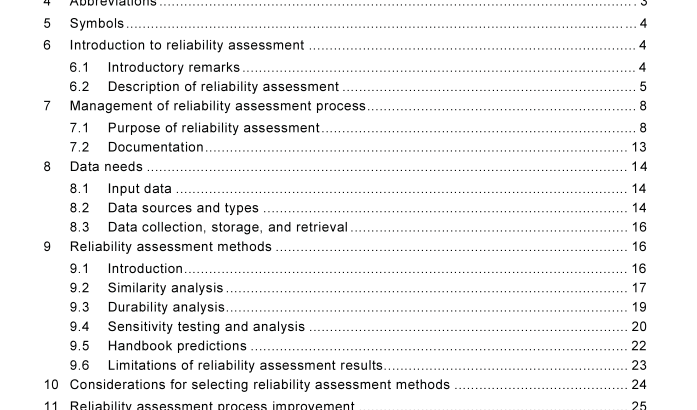

The following is a list of methods commonly used for assessing reliability:

− similarity analysis;

− durability analysis;

− handbook methods.