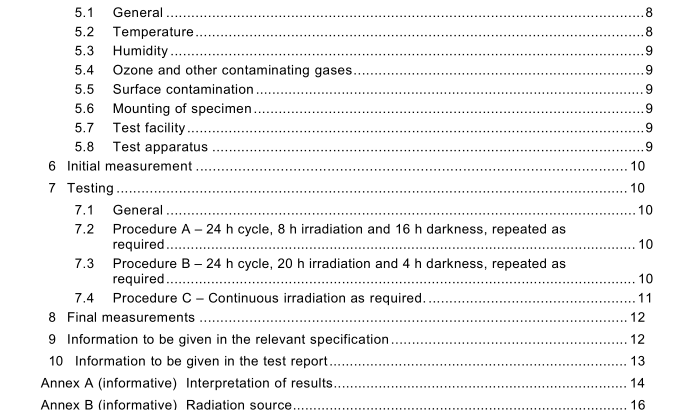

IEC 60068-2-5:2010 pdf download – Environmental testing – Part 2-5: Tests – Test Sa: Simulated solar radiation at ground level and guidance for solar radiation testing

5.3Humidity

Different humidity conditions,particularly condensation,can markedly affect photochemicaldegradation of materials,paints,plastics,etc. lf required,the values of lEC 60068-2-78 shallbe preferred.

The relevant specification shall state the humidity and whether it is to be maintained duringa) the irradiation periods only;

b) the periods of darkness only;c) the whole test duration.

5.4ozone and other contaminating gases

Ozone,generated by short wavelength ultra-violet of test sources,will normally be excludedfrom the test chamber by the radiation filter(s) used to correct the spectral energy distribution.As ozone and other contaminating gases can significantly affect the degradation processes ofcertain materials,it is important to exclude these gases from the test chamber,unlessotherwise required by the relevant specification.

5.5Surface contamination

Dust and other surface contamination may significantly change the absorption characteristicsof irradiated surfaces. Unless otherwise required,specimens should be tested in a cleancondition.However,if effects of surface contamination are to be assessed, the relevantspecification should include the necessary information on preparation of surfaces, etc.

5.6 Mounting of specimen

The specimen to be tested shall be placed either on raised support, on a turntable or aspecified substrate of known thermal conductivity and thermal capacity within the chamber asstated in the relevant specification,and so spaced from other specimens as to avoid shieldingfrom the source of radiation or re-radiated heat.Temperature sensors should be attached tospecimen as required.

5.7Test facility

lt shall be ensured that the optical parts of the test facility, lamps, reflectors and filters,etc. areclean.

The level of irradiation over the specified measurement plane shall be measured immediatelyprior to each test.

Any ancillary environmental conditions,e.g. ambient temperature,humidity and otherparameters if specified,should be monitored continuously throughout the test.

5.8Test apparatus

The chamber in which the tests are to be carried out shall be provided with means forobtaining, over the prescribed irradiation measurement plane, an irradiance of 1 120 W/m2±10 % with the spectral distribution given in Table 1.The value of 1 120 W/m2 shall includeany radiation reflected from the test chamber and received by the specimen under test. ltshould not include long-wave infra-red radiation emitted by the test chamber.

Means shall also be provided whereby the specified conditions of temperature, air flow andhumidity can be maintained within the chamber.

The temperature within the chamber shall be measured (with adequate shielding from radiatedheat) at a point or points in a horizontal plane 0 mm to 50 mm below the prescribed irradiationmeasurement plane, at half the distance between the specimen under test and the wall of thechamber, or at 1 m from the specimen, whichever is the lesser.

6 lnitial measurement

The specimen shall be submitted to the visual,dimensional and functional checks prescribedby the relevant specification.

7 Testing

7.1General

During exposure, the temperature within the chamber shall rise or fall by 1 K/min and bemaintained at one of the preferred values given in lEC 60068-2-1 or IEC 60068-2-2 or therelevant specification.

ln procedure A, the temperature within the chamber shall start to rise 2 h before the irradiationperiod starts.

During the darkness period in procedures A and B, the temperature within the chamber shallfall approximately with 1 K/min and be maintained at +25 ℃. lf the required temperature islower than 25°C, the temperature shall be maintained at the required temperature.

The requirements for irradiation,temperature and time relationships are given in Figure 2.Throughout the specified test duration, the temperature within the chamber shall be maintainedwithin +2C of that shown for the appropriate procedure.

The level of irradiance should be 1 120 w/m2±10 % or specified in the relevant specification.Acceleration of the test by increasing the irradiation above this level is not recommended.Thetotal daily irradiation approximating the most severe natural conditions is simulated byprocedure A with a duration of exposure to the standard irradiation conditions of 8 h per day.Thus,exposure for periods in excess of 8 h will effect acceleration over natural conditions.However,continuous exposure of 24 h per day,procedure C,might mask any degradationeffects of cyclic thermal stressing,and this procedure is therefore not generally recommendedin this instance.

The specimen shall be exposed, for the duration called for in the relevant specification, to oneof the following test procedures (see Figure 2).