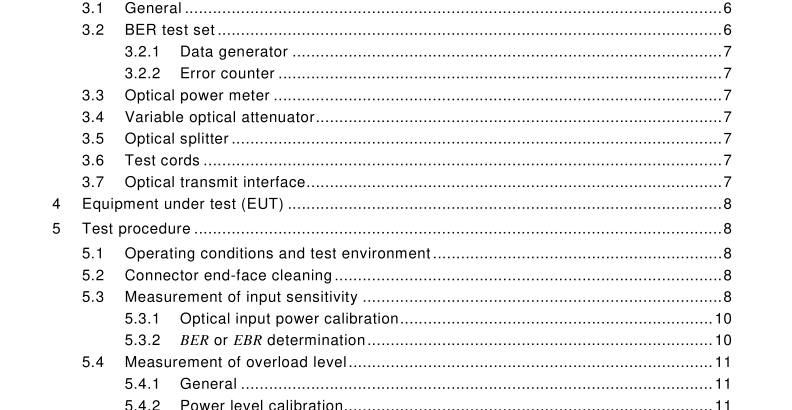

IEC 61280-2-1:2010 pdf download – Fibre optic communication subsystem test procedures – Part 2-1: Digital systems – Receiver sensitivity and overload measurement

3.2.1 Data generator

The data generator of the BER test set shall be capable of providing a data input to the system which may be a pseudo-random sequence or otherwise specified bit pattern with the signal format (pulse shape, amplitude, etc.) that is consistent with the requirements at the system input interface of the EUT. As a minimum requirement the data generator shall be capable of providing the following output date formats; other data formats may be used in compliance with the system requirements.

• a 2 23 -1 pseudo-random data stream;

• an all 1 data stream;

• a 1 + 1 5 zeros data stream. The format (pulse shape, amplitude, etc.) of the test signal shall be compliant with that required at the transmit input interface. The receiver portion of the test equipment shall be able to interface with the system output for the measurement of digital errors.

3.2.2 Error counter The error counter of the BER test set shall be able to interface with the output of the EUT. It shall be capable counting single errors or errored blocks at the data rate of system output interface of the EUT. If the error counter has the facility for computing the BER or EBR value it must be capable of calculating a value as low as 1 0 –1 2 .

3.3 Optical power meter The optical power meter used shall have a resolution of at least 0,1 dB, shall be data format and bit rate independent and shall have been calibrated for the wavelength and power range of operation for the equipment to be tested. All measurements shall be recorded on the dB scale.

3.4 Variable optical attenuator The optical attenuator shall be capable of attenuation in steps less than or equal to 0,25 dB and should be able to provide a total attenuation that is at least 5 dB greater than the specified input range of the receiver under test. Care should be taken to avoid back reflection into the transmitter.

3.5 Optical splitter The optical splitter (coupler) shall have one input port and two output ports equipped with appropriate connectors. The splitting ratio for the output ports should be 50 % ± 0,1 dB (unless otherwise specified).

3.6 Test cords Single-mode or multimode fibre reference test cords and fitted with the appropriate connectors as required by the application shall be used, unless otherwise agreed. The optical loss of the test cords including connectors shall not exceed 1 ,0 dB.

3.7 Optical transmit interface The optical transmit interface shall have electrical and optical characteristics similar to those of transmitters that are used in the specified fibre optic terminal devices, except that the output power shall exceed the maximum specified input power of the receiver by at least 2 dB.

4 Equipment under test (EUT) The EUT shall be a fibre optic receiver, optical amplifier or optical regenerator, including all associated signal conditioning, processing and multiplexing equipment used in the system under normal operating conditions. The system input and output terminations shall be those normally seen by the user of the system.

5 Test procedure The test procedure consists of the following steps.

5.1 Operating conditions and test environment Unless otherwise specified, normal operating conditions apply. The ambient or reference point temperature and humidity shall be specified. Switch on the EUT and all test equipment (apply any special operating conditions to the EUT if required) and allow 30 min. (unless otherwise specified) for the equipment to reach a steady-state temperature and performance condition.

5.2 Connector end-face cleaning Whenever optical connections are changed, the end faces of the connectors shall be cleaned. Cleaning equipment (including apparatus, materials, and substances) and the methods to be used shall be suitable for the connectors to be cleaned. Connector suppliers’ instructions shall be consulted where doubt exists as to the suitability of particular equipment and cleaning methods.

5.3 Measurement of input sensitivity Connect the equipment as shown in Figure 2, if terminal equipment is tested, or Figure 3, if an amplifier or regenerator is tested, and set the data generator and error counter to operate with a pseudo random sequence with word length of 2 23 -1 (unless otherwise specified).