IEC 61858:2008 pdf download – Electrical insulation systems – Thermal evaluation of modifications to an established wire-wound EIS

5Evaluation of the change of thickness of an EIM5.1 samples

Representative samples of the established EIs (the reference ElS) and of the EIs withreduced EIM thickness(es) (the candidate EIS) shall be evaluated in accordance withClause 10.

5.2Acceptance

A candidate EIS that meets the acceptance criteria according to Clause 10 shall be assignedthe same thermal class as the established EIS.

lf the results of the candidate ElS testing are outside the acceptance criteria according toClause 10, then full thermal ageing in accordance with IEC 61857-1 shall be conducted inorder to establish its thermal class.

NOTE Full thermal ageing may be accomplished by testing at additional temperatures, according to lEC 61857-1.

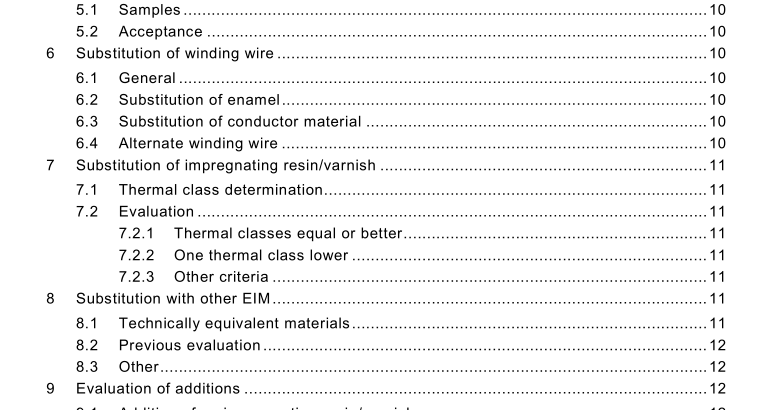

6 substitution of winding wire

6.1General

Substitution of a winding wire evaluated in the established EIS can be made without additionaltesting when one or more of the following conditions have been met:

a) the winding wire conforms to an IEC 60317 specification having the same chemical composition,according to the Annex A groupings, as the winding wire evaluated in theestablished EIs but is of a different size or shape;

b) the winding wire conforms to an lEC 60317 specification having the same chemical composition,according to the Annex A groupings, as the winding wire evaluated in theestablished EIS and has an equal or higher thermal class;

c) the winding wire is a bare conductor insulated with one of the EIM evaluated as part of the established ElS in accordance with lEC 61857-1.The thickness to be used shall be suchthat the electrical stress per unit thickness is not greater than the stress to which the EIMwas subjected during the ageing test.

NOTE For substitution of an alternate EIM,refer to Clause 8.6.2Substitution of enamel

For chemical composition substitution criteria, refer to Annex A.6.3substitution of conductor material

An established EIS,which has been evaluated with copper as the conductor, may use eithercopper or aluminium conductor.

An established ElS,which has been evaluated with aluminium as the conductor,may useeither aluminium or copper conductor,provided the thermal performance of the substitutewinding wire has been established to be equal to or better than the winding wire evaluated.

6.4Alternate winding wire

Winding wires that do not meet the criteria in 6.1 or 6.2 shall be evaluated in accordance withlEC 61857-1.

7 Substitution of impregnating resin/varnish

7.1 Thermal class determination

The thermal classes of both the candidate resin/varnish and the resin/varnish used in the established EIS shall be determined by comparison of the manufacturer’s thermal ageing data using the test methods in Table 1 . Both tests shall be conducted.

7.2Evaluation

7.2.1 Thermal classes equal or better

When both thermal classes of the candidate impregnating resin/varnish (twisted pair andhelical coil) are equal to or higher than the thermal classes of the impregnating resin/varnishin the established Els, then substitution is allowed:

a) based on acceptable results when tested for compatibility using the procedure from Annex B,or

b) based on acceptable results when tested according to Clause 10.7.2.2One thermal class lower

lf one or both of the thermal classes of the candidate impregnating resin/varnish (twisted pairand/or helical coil) are no more than one thermal class lower than the thermal classes of theimpregnating resin/varnish of the established ElS, then substitution is allowed based onacceptable results when tested in accordance with Clause 10.

NOTE lf the established Els has received its thermal class rating without the inclusion of an impregnatingresin/varnish, refer to 9.1 for addition of an impregnating resin/varnish.

7.2.3Other criteria

Aresin/varnish not meeting the above criteria shall be evaluated according toIEC 61857-1.

8Substitution with other EIM8.1 Technically equivalent materials Substitution with EIM,which have an identical chemical composition, is acceptable with noadditional testing. Substitution or addition of select additives in an EIM may be allowed withreduced or no additional testing (if agreed upon by all interested parties).