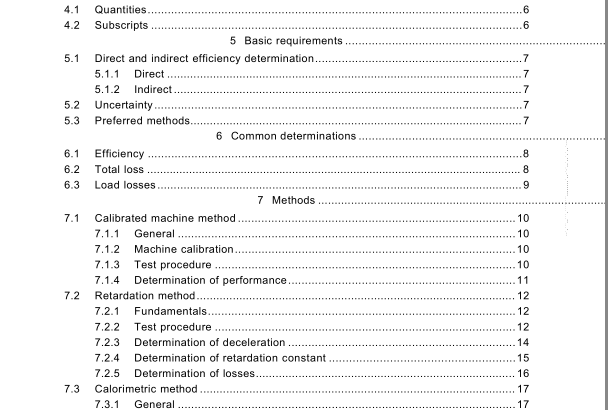

IEC 60034-2-2:2010 pdf download – Rotating electrical machines – Part 2-2: Specific methods for determining separate losses of large machines from tests – Supplement to IEC 60034-2-1

1 Scope

This part of lEC 60034 applies to large rotating electrical machines and establishes additionalmethods of determining separate losses and to define an efficiency supplementingIEC 60034-2-1.These methods apply when full-load testing is not practical and result in agreater uncertainty.

NOTE ln situ testing according to the calorimetric method for full-load conditions is recognized.The specific methods described are:

-Calibrated-machine method.-Retardation method.

-Calorimetric method.

2Normative references

The following referenced documents are indispensable for the application of this document.For dated references, only the edition cited applies.For undated references, the latest editionof the referenced document (including any amendments) applies.

IEC 60034-1, Rotating electrical machines – Part 1: Rating and performance

IEC 60034-2-1,Rotating electrical machines – Part 2-1: Standard methods for determininglosses and efficiency from tests (excluding machines for traction vehicles)

3Terms and definitions

For the purposes of this document,the terms and definitions given in IEC 60034-1 andlEC 60034-2-1 apply, as well as the following.

3.1

calibrated machine

machine whose mechanical power input/output is determined,with low uncertainty,usingmeasured electrical output/input values according to a defined test procedure

3.2

calibrated-machine method

method in which the mechanical inputloutput to/from an electrical machine under test isdetermined from the measurement of the electrical input/output of a calibrated machinemechanically coupled to the test machine

3.3

retardation method

method in which the separate losses in a machine under test are deduced from themeasurements of the deceleration rate of its rotating components when only these losses arepresent

4 Symbols

In addition to the symbols in IEC 60034-2-1 , the following apply.

4.1 Quantities

A is an area, m 2 ,

C is the retardation constant, kg m 2 min 2 ,

c p is the specific heat capacity of the cooling medium, J/(kg K),

h is the coefficient of heat transfer, W/(m 2 K),

J is the moment of inertia, kg m 2 ,

n is the speed, min –1 ,

P 1E is the excitation power supplied by a separate source, W,

P k is the constant loss, W,

P el is the electrical power, excluding excitation, W,

P e is the excitation power, W,

P Fe is the iron loss, W,

P fw is the friction and windage loss, W,

P sc is the short-circuit loss, W,

P mech is the mechanical power, W,

P T is the total loss, W,

Q is the volume rate of flow of the cooling medium, m 3 /s,

t is the time, s,

v is the exit velocity of cooling medium, m/s,

5Basic requirements

5.1 Direct and indirect efficiency determinationTests can be grouped in the following categories.

5.1.1Direct

Input-output measurements on a single machine are considered to be direct. This involves themeasurement of electrical or mechanical power into, and mechanical or electrical power out ofa machine.

5.1.2Indirect

Measurements of the separate losses in a machine under a particular condition areconsidered to be indirect. This is not usually the total loss but comprises certain losscomponents. The method may, however, be used to calculate the total loss or to calculate aloss component.

The determination of total loss shall be carried out by one of the following methods:- direct measurement of total loss;

-summation of separate losses.

NOTE The methods for determining the efficiency of machines are based on a number of assumptions. Therefore,it is not possible to make a comparison between the values of efficiency obtained by different methods.

5.2Uncertainty

Uncertainty as used in this standard is the uncertainty of determining a true efficiency.ltreflects variations in the test procedure and the test equipment.

Although uncertainty should be expressed as a numerical value, such a requirement needssufficient testing to determine representative and comparative values. This standard uses thefollowing relative uncertainty terms:

“low” applies to efficiency determinations based solely upon test results;

“medium” applies to efficiency determinations based upon limited approximations;- “high” applies to efficiency determinations based upon assumptions.

5.3Preferred methods

lt is difficult to establish specific rules for the determination of efficiency. The choice of test tobe made depends on the information required, the accuracy required, the type and size of themachine involved and the available field test equipment (supply, load or driving machine).