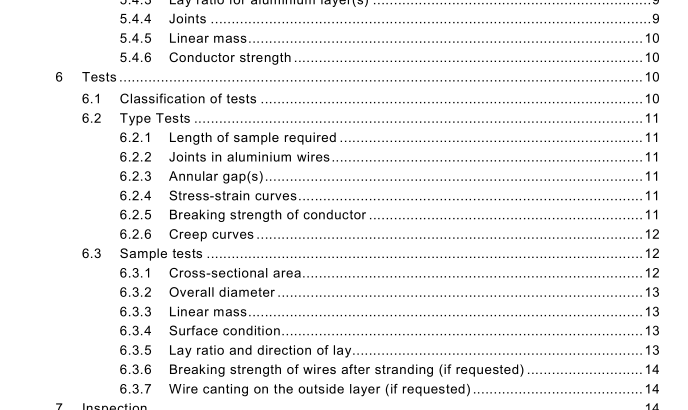

IEC 62420:2008 pdf download – Concentric lay stranded overhead electrical conductors containing one or more gap(s)

5.3 Surface

The surface of the conductor shall be free from all imperfections visible to the unaided eye (normal corrective lenses accepted), such as nicks, indentations, etc., not consistent with good commercial practice. 5.4 Stranding

5.4.1 General All wires of the conductor shall be concentrically stranded. Before stranding, aluminium and core wires shall have approximately uniform temperature. Adjacent wire layers shall be stranded with reverse lay directions. The direction of lay of the external layer shall be right-hand except when specifically indicated in the purchase order.

5.4.2 Lay ratio for core wires The lay ratios for the zinc-coated (galvanised) steel or aluminium-clad wire layers shall be as follows: a) the lay ratio for the six-wire layer of the core shall be not less than 1 6 nor more than 26;

b) the lay ratio for subsequent core layers shall be not less than 1 4 nor more than 22. The lay ratio of subsequent layer(s) shall be not greater than the lay ratio of the core layer immediately beneath it. All core wires shall lie naturally in their position in the stranded core, and where the core is cut, the wire ends shall remain in position or be readily replaced by hand and then remain approximately in position.

5.4.3 Lay ratio for aluminium layer(s) The lay ratios for the aluminium layer(s) shall be as follows:

a) the lay ratio for the outside layer of aluminium wires shall be not less than 1 0 nor more than 1 4;

b) the lay ratios for the inner layers of aluminium wires shall be not less than 1 0 nor more than 1 6;

c) the lay ratio of any aluminium layer shall be not greater than the lay ratio of the aluminium layer immediately beneath it. Aluminium wires composing the outside layer of the conductor shall lie naturally in their position, and where the conductor is cut, they shall remain in position or be readily replaced by hand and then remain approximately in position.

5.4.4 Joints There shall be no joints of any kind made in the core wire or wires during stranding. There shall be no joints in the finished aluminium wire prior to stranding. During stranding, no aluminium wire welds shall be made for the purpose of achieving the required conductor length. Joints are permitted in aluminium wires unavoidably broken during stranding, provided such breaks are not associated with either inherently defective wire or with the use of short lengths of aluminium wires. Joints shall conform to the geometry of original wire, i.e. joints shall be dressed smoothly with a shape equal to that of the parent wires and shall not be kinked. Joints in aluminium wires shall not exceed those specified in Table 2. These joints shall not be closer than 1 5 m from a joint in the same wire or in any other aluminium wire of the completed conductor. Joints shall be made by electric butt welding, electric butt cold upset welding or cold pressure welding (see Note 1 ) and other approved methods. These joints shall be made in accordance with good commercial practice. The first type of joints shall be electrically annealed for approximately 250 mm on both sides of the weld. While the joints specified in this clause are not required to meet the requirements of unjointed wires (see Note 2), they shall withstand a stress of not less than 75 MPa for annealed electric butt welded joints and not less than 1 30 MPa for cold pressure and electric butt cold upset welded joints. The manufacturer shall demonstrate that the proposed welding method is capable of meeting the specified strength requirements.

NOTE 1 It is a practice in some countries to require the annealing of cold pressure joints made in A2 or A3 material.

NOTE 2 The behaviour of properly spaced wire joints in stranded conductors is related to both tensile strength and elongation. Because of higher elongation properties, the lower strength annealed electric butt welded joint gives a similar overall performance to that of a cold pressure or an electric butt cold upset welded joint.

5.4.5 Linear mass The masses given in the Table E.1 of Annex E have been calculated for each size and stranding of conductor using densities for the aluminium, aluminium-clad and zinc-coated steel wires as given in the standards listed in Clause 2, the stranding increments given in Table 3, and the cross-sectional areas for aluminium and core wires based on their theoretical unrounded values.