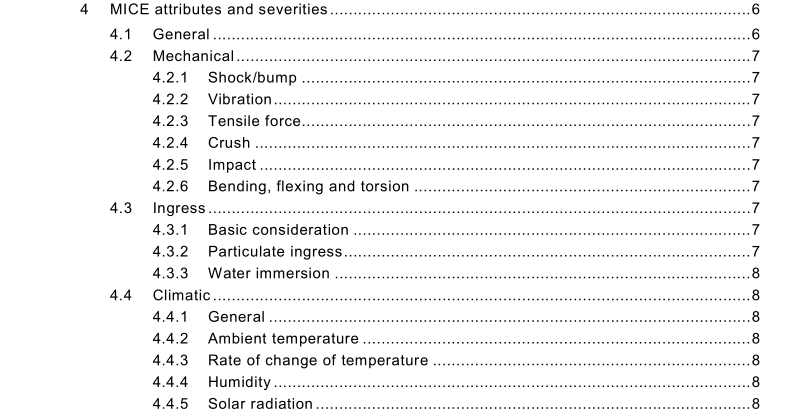

IEC TR 62362:2010 pdf download – Selection of optical fibre cable specifications relative to mechanical, ingress, climatic or electromagnetic characteristics – Guidance

4.2 Mechanical

4.2.1 Shock/bump Shock and bump are not specified for optical fibre cables. They are inherently robust in this respect. A more important attribute is bending.

4.2.2 Vibration Vibration in the industrial premises (as opposed to wind induced vibration on aerially deployed cables) is not specified for optical fibre cables. They are inherently robust in this respect.

4.2.3 Tensile force For outdoor premises cables specified in IEC 60794-3 series, manufacturers specify a rated tensile force. The requirement is that the fibre shall not exceed a percentage of the proof test strain (to be agreed between customer and supplier) when the cable is tested at the rated load. For indoor cables, the different family specifications of IEC 60794-2 series have different requirements on the tensile load.

4.2.4 Crush For optical fibre cables, the crushing force is applied in a plate to plate test. For indoor cables, crush is specified at 500 N. For outdoor cables, different levels are specified depending on whether the cable is armoured or not. For unarmoured cable, values of between 1 500 N and 3 000 N may be specified. For armoured cable, values between 2 200 N and 1 0 000 N may be specified.

4.2.5 Impact For indoor cables a value of 1 J with a 1 2,5 mm radius is specified. For un-armoured outdoor cables, a value of either 1 0 J with a 300 mm radius or 3 J with a 1 0 mm radius is specified.

4.2.6 Bending, flexing and torsion All the family specifications have requirements on these attributes. For bending, there are multiple tests such as bending under tension, repeated bending and simple bending. The bending diameter is typically 20 times the cable diameter. For torsion, the test length, load, and number of turns varies depending on the family specification. For indoor cables, the length is from 250 mm to 1 000 mm, loaded at 20 N with 20 cycles applied.

4.3 Ingress

4.3.1 Basic consideration Optical fibre cables come in a variety of constructions. Some examples are slotted core, loose tube, tight buffered. The slotted core and loose tube can be filled or unfilled. These different constructions have different ingress characteristics.

4.3.2 Particulate ingress Particulate ingress is not specified for optical fibre cables. They are inherently robust in this respect.

4.3.3 Water immersion On cables for which water immersion is specified, the test is different from that found in Annex A. The requirement is that a pressure equivalent to 1 m of water is applied at or near one end of a short (<3m) cable. After 24 h, the requirement is: No water found at the other end. It is expected that cables passing this test would pass both I 2 and I 3 severities.

4.4 Climatic

4.4.1 General Terminations such as cable closures are generally considered separately from the cables and are covered by IEC SC 86B. NOTE The values that appear in Tables 1 to 3b below indicate levels of resistance to climatic phenomena. Values of 1 – 3 correspond to the relevant level of severity in the MICE classification system. A value of 0 indicates no effective resistance to the climatic phenomena described.

4.4.2 Ambient temperature The different specifications allow different ranges of values to be specified by the customer, depending on the climate in which the cable will be installed. For the detailed specifications for premises cabling, –20 ºC to +60 ºC are specified. Other ranges and combinations from –45 ºC to +70 ºC are also found as options in the family specifications.

4.4.3 Rate of change of temperature This is not specified. All the cables that pass the other requirements will, however, have the capability of 3 °C/min.

4.4.4 Humidity For further study.

4.4.5 Solar radiation Resistance to solar radiation in the industrial premises environment is not specified. Resistance to solar radiation is a property of the sheath material. The severities associated with some common generic materials are indicated in Table 1 . A specific grade of the generic material may have a different performance to that identified in the Table 1 .