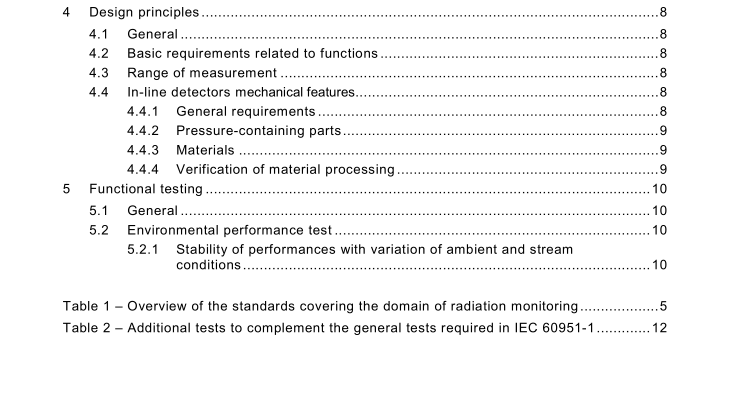

BS IEC 60951-4:2009 pdf download – Nuclear power plants – Instrumentation important to safety – Radiation monitoring for accident and post-accident conditions — Part 4: Equipment for continuous in-line or on-line monitoring of radioactivity in process streams

4 Design principles

4.1 General Except where otherwise specified, all the requirements specified in Clause 4 of IEC 60951 -1 shall be carried out, unless otherwise stated.

4.2 Basic requirements related to functions The main purpose of equipment for continuous in-line or on-line monitoring of radioactivity in process streams is to continuously measure radiation levels in appropriate pipes or tanks, either by being positioned in them (i.e. immerged in the process stream) or adjacent to them (i.e. viewing straight through the process stream). These radiation measurements are displayed locally and/or in control rooms to keep plant operators aware of current radiological conditions. This information is used for control purposes and/or initiation of protective actions. Therefore, the equipment concerned by this standard is capable of actuating alarms and providing inputs to other plant systems and processes in order to isolate processes at abnormal radiation levels. The basic requirements for the design, selection, testing, calibration and functional location of equipment for continuous in-line and on-line monitoring of radioactivity in process streams are plant specific. Process radiation monitors within the scope of this standard can be classified into two basic types: – in-line monitors: the detector is located directly in the process stream (pipe, tank, duct),

– on-line monitors: the detector faces directly the process stream. For the purpose of critical data collection, these monitors may be designed to withstand adverse environmental and seismic conditions, during and after an accident. In addition to the basic requirements of IEC 60951 -1 , the specification procedure should include the following:

– Establish the required measurement characteristics (purchaser): Determine the stream characteristics (physical, chemical and dynamic characteristics of the stream to be monitored) such as: type of fluid, thermodynamic state, temperature range and rate of change, pressure range and rate of change, radiochemical properties, etc.

4.3 Range of measurement In addition to 4.2 of IEC 60951 -1 , the following requirements shall apply: The effective range of measurement should be at least six decades.

4.4 In-line detectors mechanical features 4.4.1 General requirements Whenever in-line detectors are located in a sleeve or a piping system implanted as part of a pipe or tank under pressure or carrying hot or corrosive fluid, specific requirements shall apply to ensure thermodynamical and mechanical conditions are taken into account. When specified, the sleeve or piping system, including all accessories, shall be supplied by the detector manufacturer and fully assembled on the main pipe or tank when possible. The sleeve or piping system shall be designed and arranged to permit an easy removal of the detector for maintenance and cleaning. The detector shall be adequately installed in the sleeve or piping system to prevent damage due to vibration under normal operation and maintenance activities.

The mechanical features of piping and its connections, including bolting and sealing, shall be agreed between the purchaser and manufacturer, and shall conform to relevant standards.

4.4.2 Pressure-containing parts The maximum allowable working pressure of the detector at the most severe operating conditions shall be clearly defined by the manufacturer. In no case shall the maximum allowable working pressure of the detector and the sleeve exceed that of the sleeve flanges. Pressure casings including the detector housing shall be of such thickness as will be suitable for containing pressure and limiting distortion under the maximum allowable pressure at the operating temperature. The casing shall also be suitable for the hydrostatic test pressure at ambient temperature. The pressure-containing parts shall be made of non-corrosive materials, to be agreed upon between the purchaser and the manufacturer. The bolting selected (property class) shall be adequate for the maximum allowable working pressure of the detector sleeve and for normal tightening procedures. If at some point it is necessary to use a fastener of special quality, interchangeable fasteners for other joints shall be of the same quality.