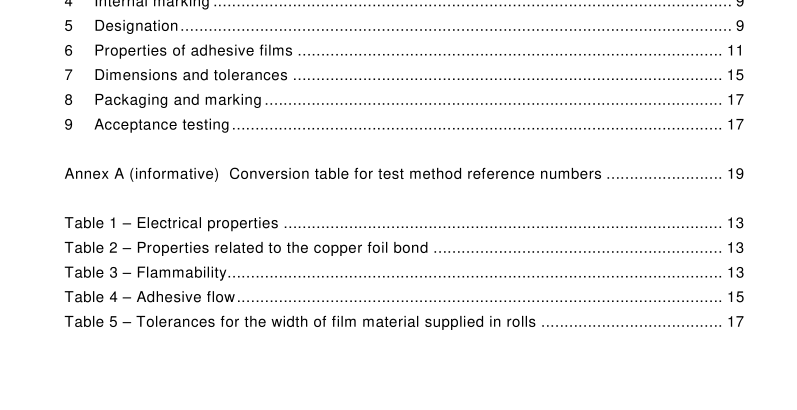

IEC 61249-3-5:2009 pdf download – Materials for printed boards and other interconnecting structures – Part 3-5: Sectional specification set for unreinforced base materials, clad and unclad (intended for flexible printed boards) – Transfer adhesive films

6 Properties of adhesive films

6.1 Appearance The adhesive film shall be free from blisters and wrinkles. There shall be no imperfections which will be detrimental to the material properties or to their intended use. The film shall be uniform in colour and free from foreign inclusions. Colour degradation shall not occur when the film is processed in accordance with the manufacturer’s instructions. The appearance of the adhesive film shall only be inspected with protective material present in cases where the protective material is transparent. Where foreign inclusions appear to be imbedded in the adhesive and/or between the adhesive and the protective materials, the pro- tective materials shall be removed and the adhesive film shall be re-inspected.

6.2 Properties of adhesive films after curing

6.2.1 Preparation of laminated specimens In order to determine the properties listed in 6.2.2 and 6.2.3, laminated samples shall be prepared as follows.

6.2.1 .1 Specimens from cover sheets Test specimens, unless for peel strength or heat shock testing, shall comply with the requirements of IEC 60249-1 . They shall be cut from a set of samples prepared by laminating copper foil to the film material under test. Laminating conditions should be agreed upon between purchaser and supplier and should comply with the material manufacturer’s recommendations regarding pressure, temperature and pressing duration. The copper foil, as used in the fabrication of copper-clad laminates, shall have a thickness of 35 µm (305 g/m 2 ) and shall be applied with the untreated (shiny) side to the adhesive layer. Samples for peel strength or heat shock testing shall be prepared by laminating with a single- sided epoxide/glass laminate on one side of the adhesive film, and with unclad epoxide/glass laminate on the second side. The minimum thickness of the unclad laminate shall be 0,5 mm. In all other respects, sample preparation shall be as detailed above. If any argument arises in relation to the laminating conditions, it is desirable to apply the standard procedures and conditions in the relevant test method specification (see IEC 61 1 89-2) by agree- ment between purchaser and supplier.