PD IEC TR 62518:2009 pdf download – Rare earth sintered magnets — Stability of the magnetic properties at elevated temperatures

4 Classification of magnetic flux loss due to temperature

4.1 Reversible flux loss The reversible change in the magnetic properties of rare earth magnets as a function of temperature originates from the change in saturation magnetization. Reversible flux loss is a magnetization change which is recovered by the removal of a disturbing influence such as temperature.

4.2 Irreversible flux loss With irreversible flux loss, after the removal of the disturbing influence, the magnetization does not return to its original value. Examples of the disturbing influence are temperature changes, local temperature fluctuations and magnetic fields. The irreversible flux loss is fully recovered by remagnetization.

4.3 Permanent flux loss

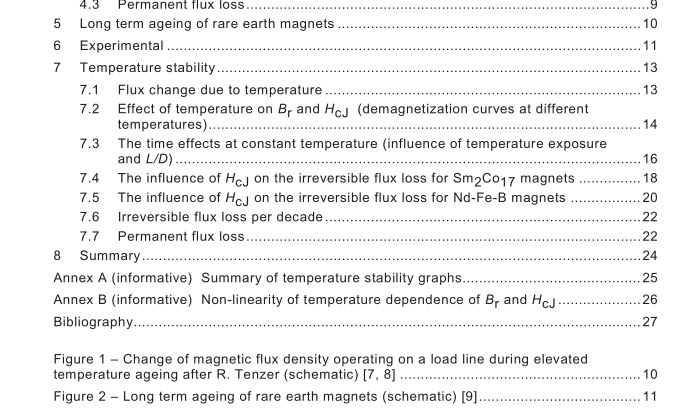

Permanent flux loss is caused by a permanent change in the metallurgical state and is generally time and temperature dependent. Examples are precipitation and growth, oxidation, the annealing effects and radiation damage. The permanent flux loss cannot be recovered to the initial magnetization value by remagnetization. The various flux losses mentioned above are shown in Figure 1 .

The figures were schematically presented by R. Tenzer [7, 8]. In Figure 1 the magnetic flux density B vs temperature and demagnetization curves at various temperatures with a certain load line are given to explain the three kinds of losses. The curves in Figure 1 (a) apply only for short temperature excursions, for example from 25°C to θ °C. Magnetic flux density B changes reversibly along a demagnetization curve at various temperatures. B d (25) – B d (θ) is called the “reversible flux loss”. This flux loss is fully recovered by returning the magnet to room temperature. Curves in Figure 1 (b) apply for larger temperature excursions. In this case a part of the flux change will be recovered on cooling, B d ‘(25) – B d ’(θ). The other part, B d (25) – B d ‘(25), can be recovered by remagnetization and is called the “irreversible flux loss”.

When the exposure temperature exceeds several hundred degrees Celsius, changes in the microstructure of the magnet, surface oxidation etc., cause an additional flux loss which will no longer be recovered by remagnetization. B d (25) – B d ∫(25) in Figure 1 (c) is called the “permanent flux loss”. The reversible B d vs θ closely reflects the temperature variation of saturation magnetization and remanence. It is commonly approximated by a straight line and is called “the reversible temperature coefficient”, see 3.4.

5 Long term ageing of rare earth magnets

When a magnet is newly magnetized and the flux (open circuit flux or its operating-point induction) is observed for a long period of time, a slow decay is found to occur. It usually follows a time function. This behaviour is shown in Figure 2 schematically after K. J. Strnat [9]. The change can be separated into three stages. First, there is a relatively fast initial flux loss, ab.

This is followed by a long period of increasing stability, marked the “plateau”, bc, during which there is often a constant irreversible flux loss per logarithmic time cycle on the plateau. This time dependency of B on the plateau is proportional to log t (t is time) from the result of the magnetic after-effect which was given by Street et al. [1 0]. To show this constant flux change, the “irreversible flux loss per decade” [the flux change per decade (%/decade)] is used. The irreversible flux loss per decade is the flux loss during the time period ranging from 1 h to 1 0 h, from 1 0 h to 1 00 h or from 1 00 h to 1 000 h.

At higher temperatures and for some magnets, the flux decline, cd, will later accelerate and is sometimes catastrophic. This was observed very clearly for rare earth bonded magnets with an improper surface treatment under harsh environment conditions. For rare earth sintered magnets only small flux changes were observed. The temperature stability correlated with the complex corrosion behaviour will not be given in this technical report.