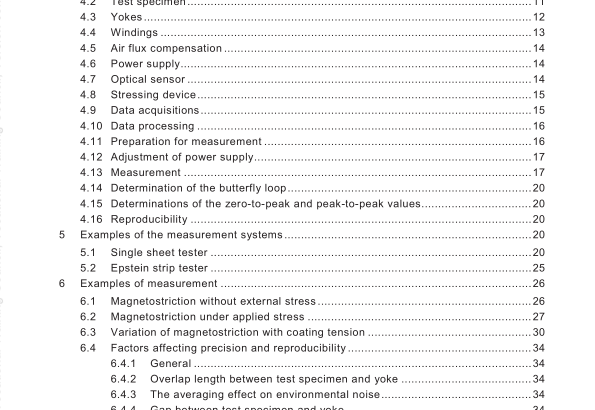

PD IEC TR 62581:2010 pdf download – Electrical steel — Methods of measurement of the magnetostriction characteristics by means of single sheet and Epstein test specimens

The test specimen comprises a sample of electrical steel sheet and is placed inside two windings:

– an external primary winding;

– an interior secondary winding. The flux closure is made by a magnetic circuit consisting of a yoke, the cross-section of which is large compared with that of the test specimen. There are narrow and homogeneous gaps between the test specimen and the pole faces of the yoke to weaken the electromagnetic force between them. The test frame that consists of the yoke, the windings and a clamp should be permanently fixed to a rigid base during the measurement. The test specimen is fixed to the base at one end of the windings using the clamp shown in Figure 1 .

An optical target is pasted on the centerline of the surface of the test specimen at the other end of the windings. Changes in length between the clamping point and the optical target are measured using an optical sensor. In order to reduce the effect of stray fields between the test specimen and the pole faces, the optical sensor should be at a sufficient working distance from the test frame.

Two measurement types of optical sensor can be used: a single point measurement and a differential measurement. The single point measurement uses a sensor head fixed on the base and measures vibration or displacement between the optical target and the sensor head. The differential measurement uses two sensor heads and measures vibration and displacement between the optical target and a reflector fixed on the base. The latter system has advantages of (a) cancellation of external noise and in (b) setting the sensors separately from the base. Care shall be taken to minimize noise vibrations caused by resonances of the test frame and external vibrations. The test frame shall be placed on an anti-vibration table in order to isolate the test frame from external vibration. Care shall be taken to prevent out-of-plane deformations of the test specimen. The test specimen shall be placed on a flat and smooth surface in the test frame and kept flat during the measurement (see Annex A).

4.2 Test specimen The length of the test specimen should be not less than 500 mm. The part of the specimen situated outside the pole faces should not be longer than is necessary to facilitate insertion and removal of the test specimen and to apply an external stress to the test specimen in the longitudinal direction. The width of the test specimen should be not less than 1 00 mm.

NOTE Since the average grain diameter for the high permeability grain-oriented electrical steel sheet is about 1 0-20 mm, a comparatively large sample size is required.

The test specimen should be wide enough to take into account the affected region close to the cut edges. However, it may be difficult to produce a flux closure yoke with flat and coplanar faces for wider test specimens. The test specimen should be cut without forming large burrs or mechanical distortion. The test specimen shall be flat. When a test specimen is cut, the edge of the parent strip is taken as the reference direction. The following tolerances are allowed for in the angle between the direction of rolling and that of cutting:

– ±1 ° for grain-oriented electrical steel sheet;

– ±5° for non-oriented electrical steel sheet.

4.3 Yokes

Several types of yoke can be used (see Figure 4):

– a horizontal single or double yoke;

– a vertical single or double yoke.

The horizontal yokes make a horizontal flux closure and the vertical yokes make a vertical flux closure. Each pole face is horizontal in both types of yoke.