IEC 60079-31:2008 pdf download – Explosive atmospheres – Part 31: Equipment dust ignition protection by enclosure “t”

4.2.1.2Protective devices

The equipment shall be protected by an integral thermal protective device. This thermalprotective device shall not be a self-resettable type and must be duplicated unless it complieswith lEC 60127 or lEC 60691,then only one device is necessary.Alternatively,if it can bedemonstrated that an overcurrent protective device can be used to provide thermal protection,such a device may be used to combine temperature protection and overcurrent protection.The overcurrent protective device shall comply with lEC 60127 and shall be rated at not morethan 170 % of the maximum rated current. When an overcurrent protective device is not alsoused as a thermal protective device, it is permissible for the overcurrent protective device tobe located outside of the enclosure of the electrical equipment. In this case, the marking shallinclude the symbol “X” in accordance with lEC 60079-0 and the Specific Conditions of Useshall detail the required overcurrent protective device.

4.2.1.3Temperature limitation

The temperature of internal devices and components shall not exceed the temperature ratingof the equipment under the test conditions of the thermal test in 6.1.2.

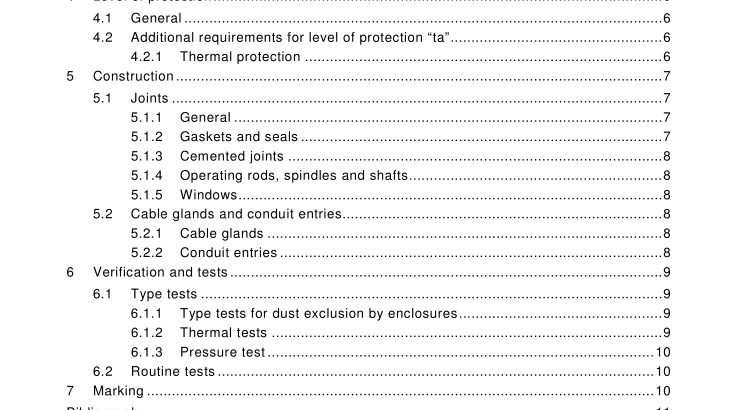

5 Construction

5.1Joints

5.1.1 General

All joints in the structure of the enclosure,whether permanently closed or designed to beopened from time to time, shall fit closely together within the tolerances specified in thedocumentation.They shall be effectively sealed against the ingress of dust and shall complywith the following particular requirements and be subjected to the test of 6.1.1:

NOTE The use of grease alone to maintain the integrity of the seal is not considered to satisfy this requirement.. The number of engaged threads for all threaded joints,employing parallel threads withoutan additional seal or gasket shall be not less than five threads,with a minimum toleranceof medium or fine according to lso 965-1 and lso 965-3.

Hinges shall not be used as a means of maintaining a seal unless:

– correct compression of the gasket is achieved without causing undue movement,

stress or distortion to the gasket; and

they are manufactured from materials that would not give rise to sufficient wear thatmay affect the correct function of the sealing means .

Where necessary,a means shall be provided for mating parts to facilitate correct alignment.

5.1.2Gaskets and seals

Gaskets under compression in joints may be used to ensure the effectiveness of theenclosure sealing.

All gaskets and seals shall be of one-piece continuous construction, i.e. with an uninterruptedperiphery.

NOTE1 One-piece construction would also include gaskets and seals that have been permanently joined to forman uninterrupted periphery while maintaining the mechanical properties of the gasket or seal material.

Except for a slight amount of lubricant necessary for assembly, joints using gaskets shall notbe supplemented by the application of a sealant material except for an adhesive material onone side of the mating surfaces.

A flexible seal, e.g. a bellows, shall be such that it is not over-stressed at any point and shallbe protected from external mechanical damage and secured at each end by mechanicalmeans.

5.1.3Cemented jointsCemented joints shall not:

be used on mating parts,which need to be removed to gain access to field wiringconnections or in-service adjusting facilities; and

. have a width less than 3 mm.

5.1.4Operating rods, spindles and shafts

Openings in enclosures for rods,spindles or shafts shall have means to inhibit the ingress ofdust,other than only grease or compound, both when the spindles, rods or shatts are inmotion and when they are at rest.

5.1.5Windows

5.1.5.1 Windows employing a cemented joint

A window design employing a cemented joint shall be such that it is cemented either directlyinto the wall of the enclosure so as to form with the latter an inseparable assembly, or into aframe such that the assembly can be replaced as a unit.

5.1.5.2 Windows employing a gasket joint

A window design employing a gasket for dust exclusion shall be such that it is mounteddirectly in the wall or cover of the enclosure. No separate detachable frame is required.

5.2Cable glands and threaded entries

5.2.1Cable glands

Cable glands,whether integral or separate,shall meet the requirements of lEC 60079-0, andthe joint requirements of 5.1. In addition to these requirements, cable glands for “ta” shall besubjected to the tests of 6.1.1.

Where cable glands are integral with the enclosure or specific to the enclosure they shall betested as part of the enclosure.