IEC 61467:2008 pdf download – Insulators for overhead lines – Insulator strings and sets for lines with a nominal voltage greater than 1 000 V – AC power arc tests

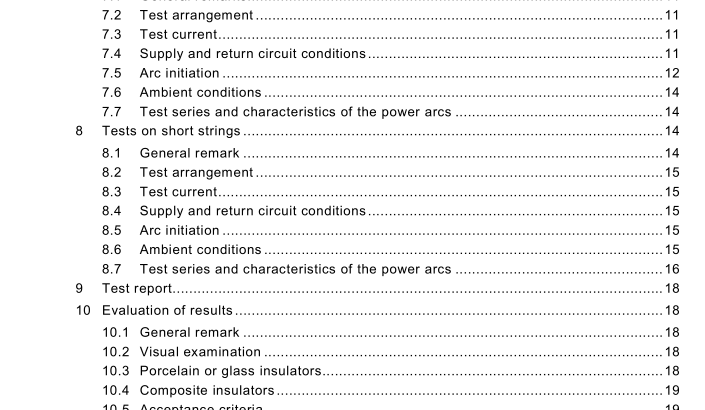

7 Tests on insulator sets

7.1 General remarks The test procedure for insulator sets described in this standard consists of two possible series of three power arc applications (sequences) at different current levels and of different duration. This test procedure is intended to cover fault current conditions occurring at representative points along a line.

The test procedure is also intended to reproduce pollution- induced power arc flashover, which creates the most severe conditions. As the test procedure for insulator sets described in this standard is intended to simulate conditions encountered in service, attention is drawn to the fact that it is not possible to extrapolate the behaviour of an insulator set of a given length to that of an insulator set of different length or equipped with fittings of different design or materials.

7.2 Test arrangement

The test arrangement shall duplicate the actual configuration of the complete insulator set and as closely as possible that of the conductor and of the part of the tower nearest to the insulator set. The actual protective fittings shall be used and their position with respect to the insulator units, the clamps and the conductor shall be reproduced.

The aim of the true simulation of the actual configuration is to recreate the real electromagnetic field affecting the arc movement.

The distances between the insulator set and the grounded structures simulating the tower shall be the same as for the service configuration. In the case of some insulator sets (e.g. extra high voltage, special configurations), the actual simulation of the tower may be limited by the facilities of test laboratories. In the case of long insulator sets (L B > 6 m), a distance D of 6 m between tower and line conductors is sufficient.

The distance from the conductors to the ground plane shall be at least L B /2 or 3 m for L B > 6 m. The test arrangement shall include a conductor or conductor bundle having characteristics similar to the one used in service.

To create the real electrodynamic forces affecting the arc movement, the conductor length on both sides of the insulator sets shall be at least equal to the insulator set length but its minimum length shall be 2,5 m. In the case of long insulator sets (L B > 6 m), a conductor length L S of 6 m is sufficient (see Annex A). Some appropriate test arrangements and tower simulations (return circuit) are shown in Annex A. In order to avoid poor electrical contacts and to ensure that the insulator set is correctly positioned, a mechanical load shall be applied to the insulator set. In the case of vertical insulator sets, this load can be applied by means of a suitable weight suspended from the suspension clamp or conductor by means of an insulated link.

The value of the load shall be at least 5 kN on the complete insulator set. In the case of tension insulator sets, a higher mechanical load may be necessary to reproduce the service angle of the insulator set (see Figure A.4).

7.3 Test current The characteristics of the test current shall be in accordance with Clause 5.

7.4 Supply and return circuit conditions The supply and return circuits shall be chosen to represent the service conditions being simulated (see Clause 6)

7.5 Arc initiation The arc shall be initiated by fusible wire of a low resistance material (e.g. silver, aluminium, copper) with a maximum total cross-section of 1 mm 2 . If more than one wire is used, they shall be twisted together in parallel.

NOTE If there are problems in initiating the arc, a larger diameter fusible wire may be used. However it should be noted that this can have an adverse effect on the test result due to reduced initial arc mobility and deposition of metal on the insulator surface.

The aim of the specified arc initiation is to create conditions similar to that of a flashover occurring on a contaminated insulator set. This kind of flashover can cause the arc to root on intermediate points along the string. The description of the arcing phenomenon and the detailed explanation of the positioning of fusible wires are given in Annex D.