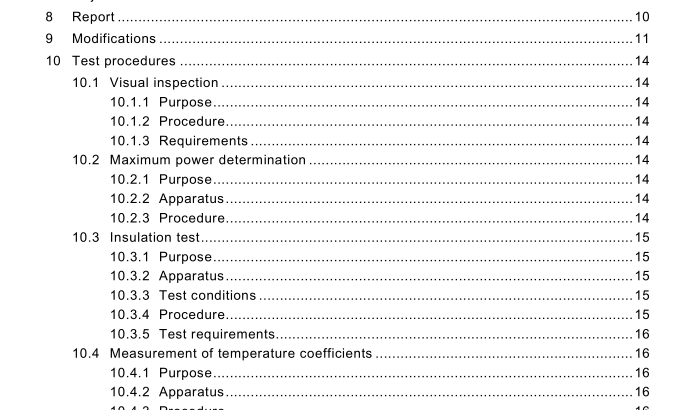

IEC 61646:2008 pdf download – Thin-film terrestrial photovoltaic (PV) modules – Design qualification and type approval

5 Testing The modules shall be divided into groups and subjected to the qualification test sequences in Figure 1 , carried out in the order laid down. Each box refers to the corresponding subclause in this standard. Test procedures and severities, including initial and final measurements where necessary, are detailed in Clause 1 0. However, with regard to the tests of 1 0.2, 1 0.4, 1 0.6 and 1 0.7, it should be noted that the procedures laid down in IEC 60891 for temperature and irradiance corrections to measured I-V characteristics apply only to linear modules. Use IEC 60904-1 0 to assess linearity. If the module is non-linear, these tests shall be carried out within ±5 % of the specified irradiance and within ±2 °C of the specified temperature.

NOTE 1 Where the final measurements for one test serve as the initial measurements for the next test in the sequence, they need not be repeated. In these cases, the initial measurements are omitted from the test. For diagnostic purposes, intermediate measurements of maximum power (1 0.2) may be undertaken before and after individual tests.

NOTE 2 The control module should be stored in accordance with the manufacturer’s recommendation. Any single test, executed independently of a test sequence, shall be preceeded by the initial tests of 1 0.1 , 1 0.2 and 1 0.3. In carrying out the tests, the tester shall strictly observe the manufacturer’s handling, mounting and connection instructions. Tests given in 1 0.4, 1 0.5, 1 0.6 and 1 0.7 may be omitted if future IEC 61 853 has been or is scheduled to be run on this module type. Thin film technologies can have different stabilization characteristics. It is impossible to define a single stabilisation procedure applicable to all thin film technologies.

This procedure tests the modules “as received“ and attempts to reach a stabilised condition before final test. Test conditions are summarized in Table 1 .

NOTE 3 The test levels in Table 1 are the minimum levels required for qualification. If the laboratory and the module manufacturer agree, the tests may be performed with increased severities.

6 Pass criteria A module design shall be judged to have passed the qualification tests, and therefore, to be IEC type approved, if each test sample meets all the following criteria:

a) after the final light soaking, the maximum output power at STC is not less than 90 % of the minimum value specified by the manufacturer in Clause 4;

NOTE The pass/fail criteria must consider the laboratory uncertainty of the measurement. As an example, if the laboratory extended uncertainty, 2 sigma of the STC measurement, is ±5 %, then a maximum power measurement greater than 85,5 % of the minimum specified value would be the pass criteria.

b) no sample has exhibited any open-circuit during the tests;

c) there is no visual evidence of a major defect, as defined in Clause 7;

d) the insulation test requirements are met after the tests;

e) the wet leakage current test requirements are met at the beginning and the end of each sequence and after the damp heat test;

f) specific requirements of the individual tests are met. If two or more modules do not meet these test criteria, the design shall be deemed not to have met the qualification requirements. Should one module fail any test, another two modules meeting the requirements of Clause 3 shall be subjected to the whole of the relevant test sequence from the beginning. If one or both of these modules also fail, the design shall be deemed not to have met the qualification requirements. If, however, both modules pass the test sequence, the design shall be judged to have met the qualification requirements.

7 Major visual defects

For the purposes of design qualification and type approval, the following are considered to be major visual defects:

a) broken, cracked, or torn external surfaces, including superstrates, substrates, frames and junction boxes;

b) bent or misaligned external surfaces, including superstrates, substrates, frames and junction boxes to the extent that the installation and/or operation of the module would be impaired;

c) voids in, or visible corrosion of any of the thin film layers of the active circuitry of the module, extending over more than 1 0 % of any cell;

d) bubbles or delaminations forming a continuous path between any part of the electrical circuit and the edge of the module;

e) loss of mechanical integrity, to the extent that the installation and/or operation of the module would be impaired;

f) Module markings (label) is no longer attached or the information is unreadable.